Laboratory Test Sieves Made in Germany

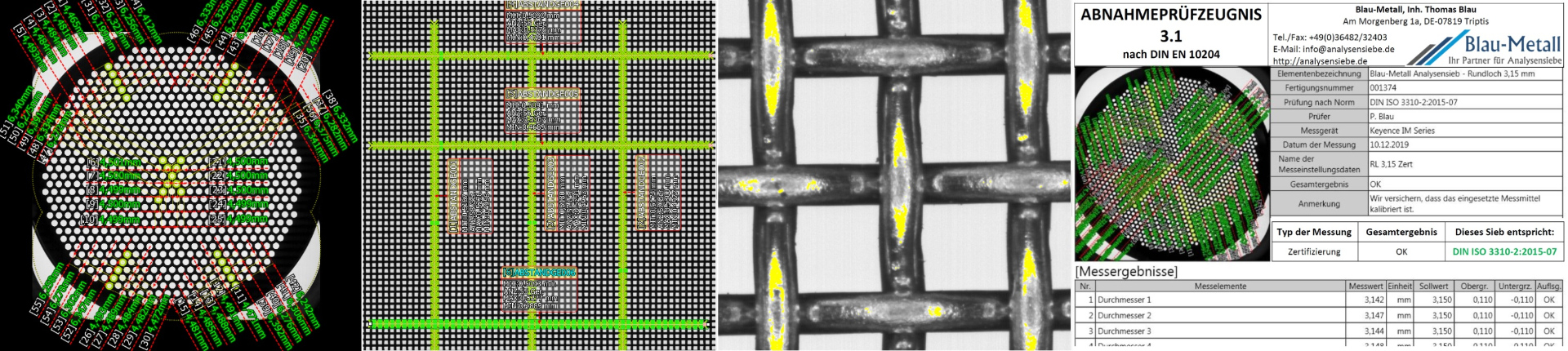

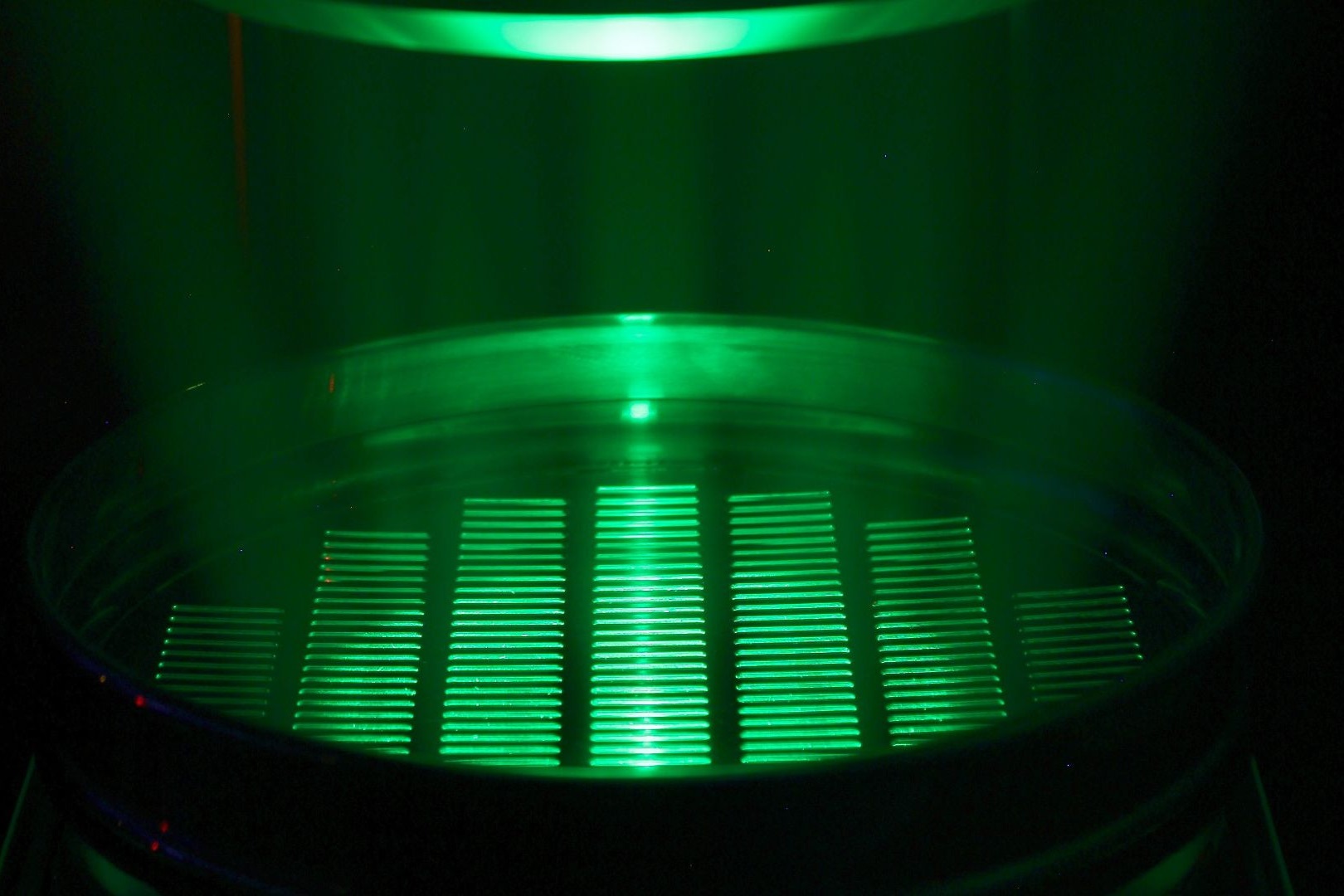

Blau-Metall specializes in laboratory test sieves conforming to a variety of national and international standards to cater to a wide range of screening tasks. Our product palette includes standard sieves with woven wire mesh or perforated plates according to ISO 3310 or the equivalent ASTM standards, specialized sieves for analysis of cereals and other scientific applications. Our Made-to-Spec Service offers custom perforation patterns of all kinds with tolerances conforming to customer requirements. End-to-end quality control relying on modern Image Dimension Measurement Technology guarantees all Blau-Metall sieves comply with the requirements of current standards.

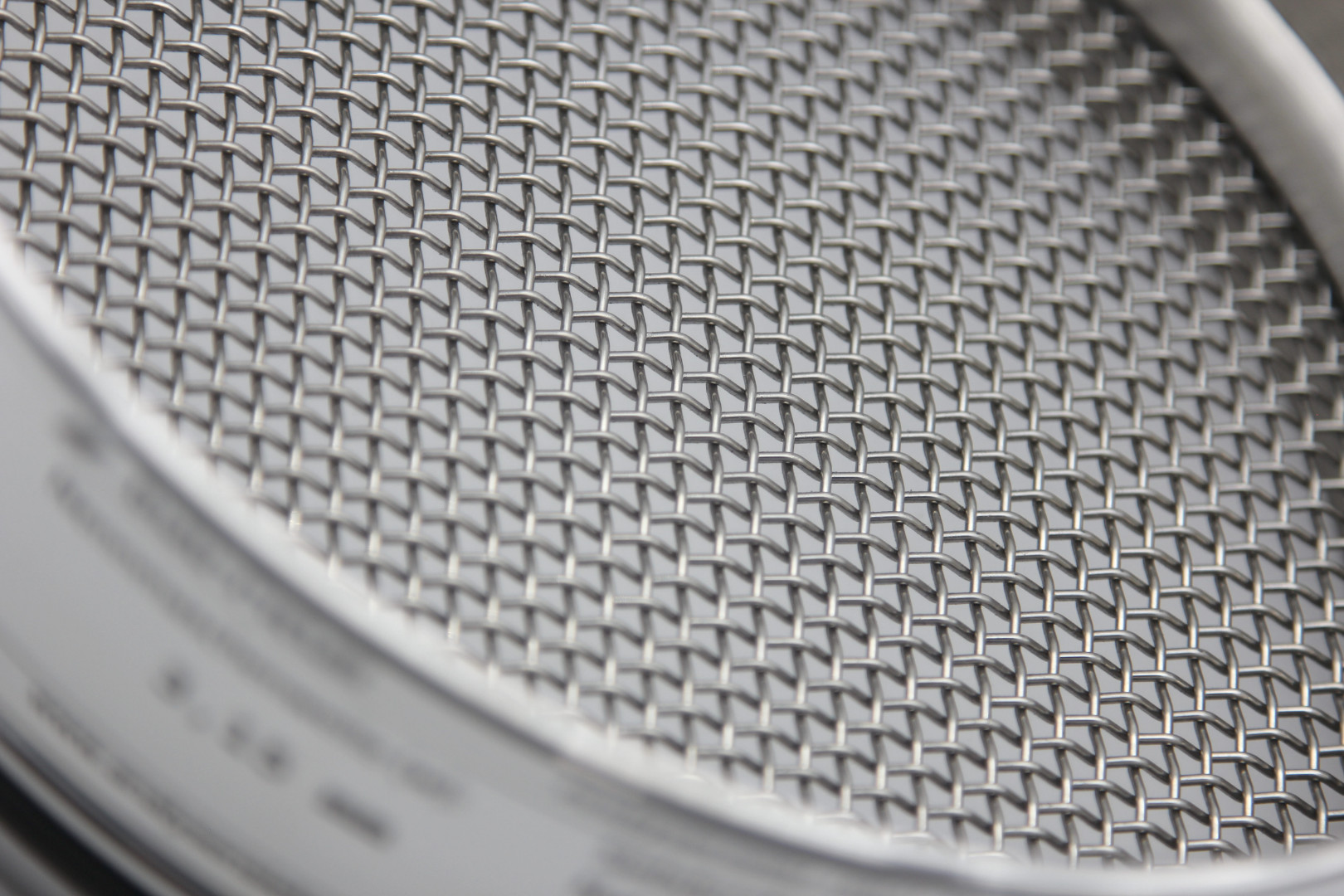

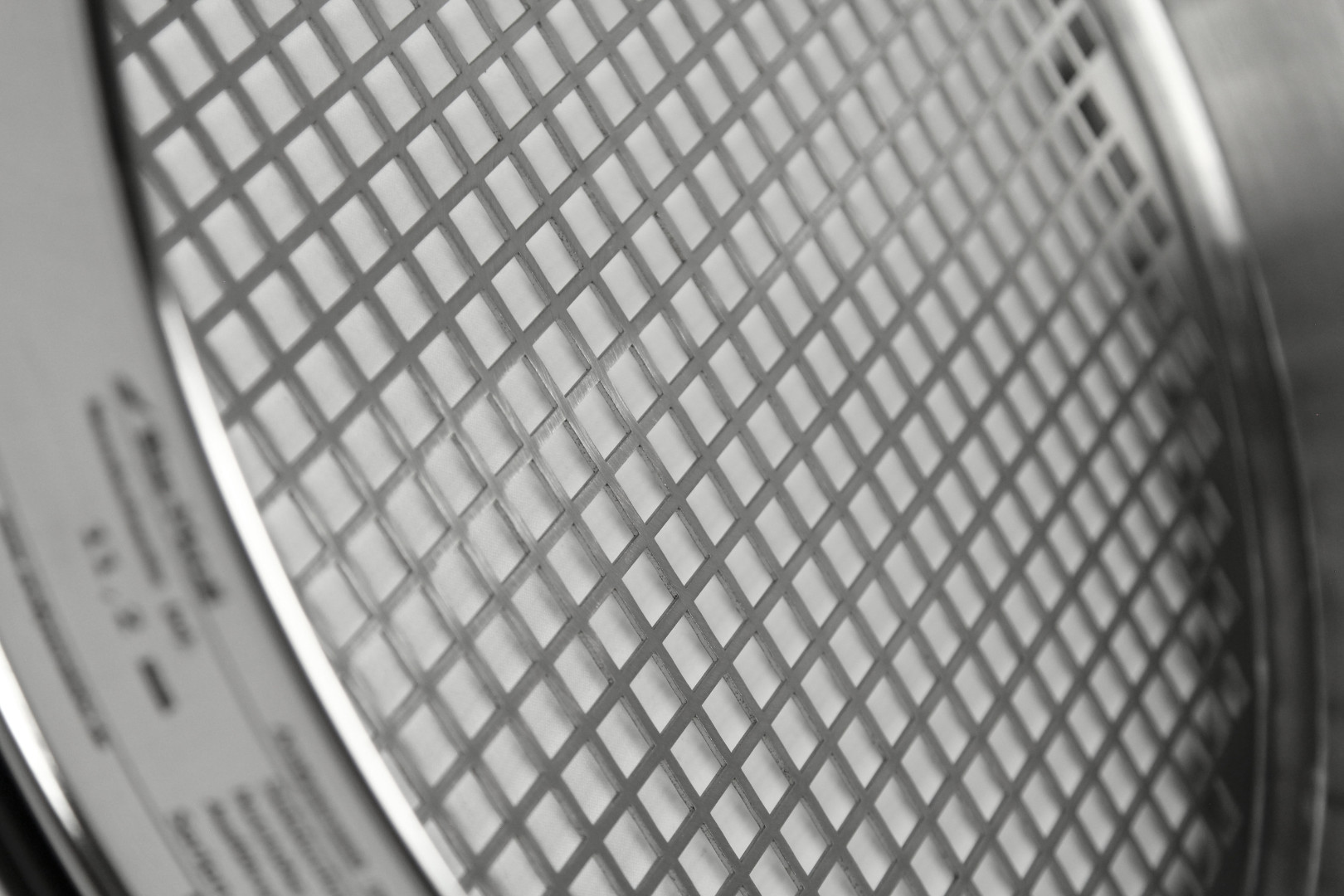

Test Sieves ISO 3310

For a broad range of industrial and scientific applications, Blau-Metall provides test sieves with woven wire cloth & perforated plate sieves with round or square openings in accordance with quality control requirements of ISO 3310.

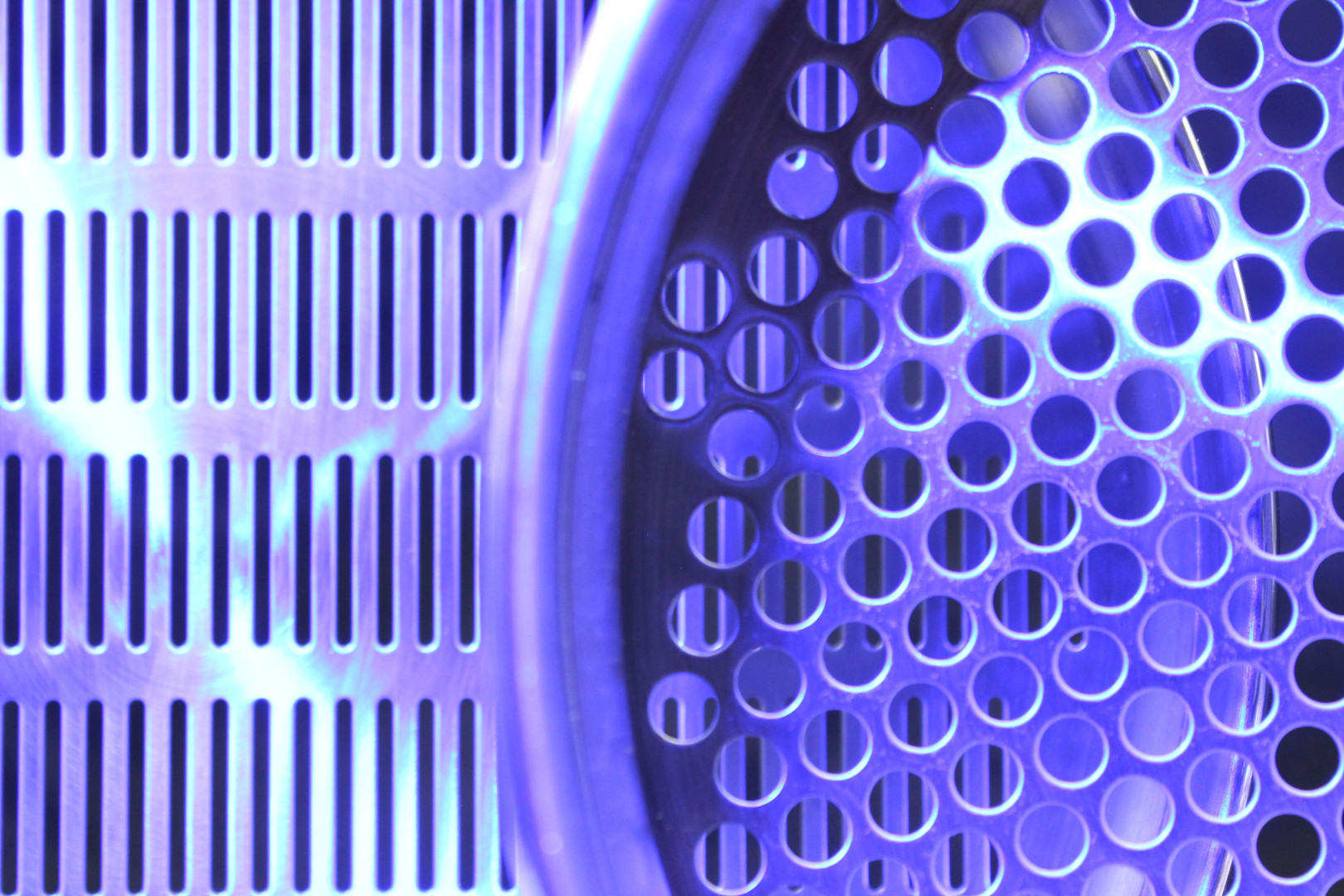

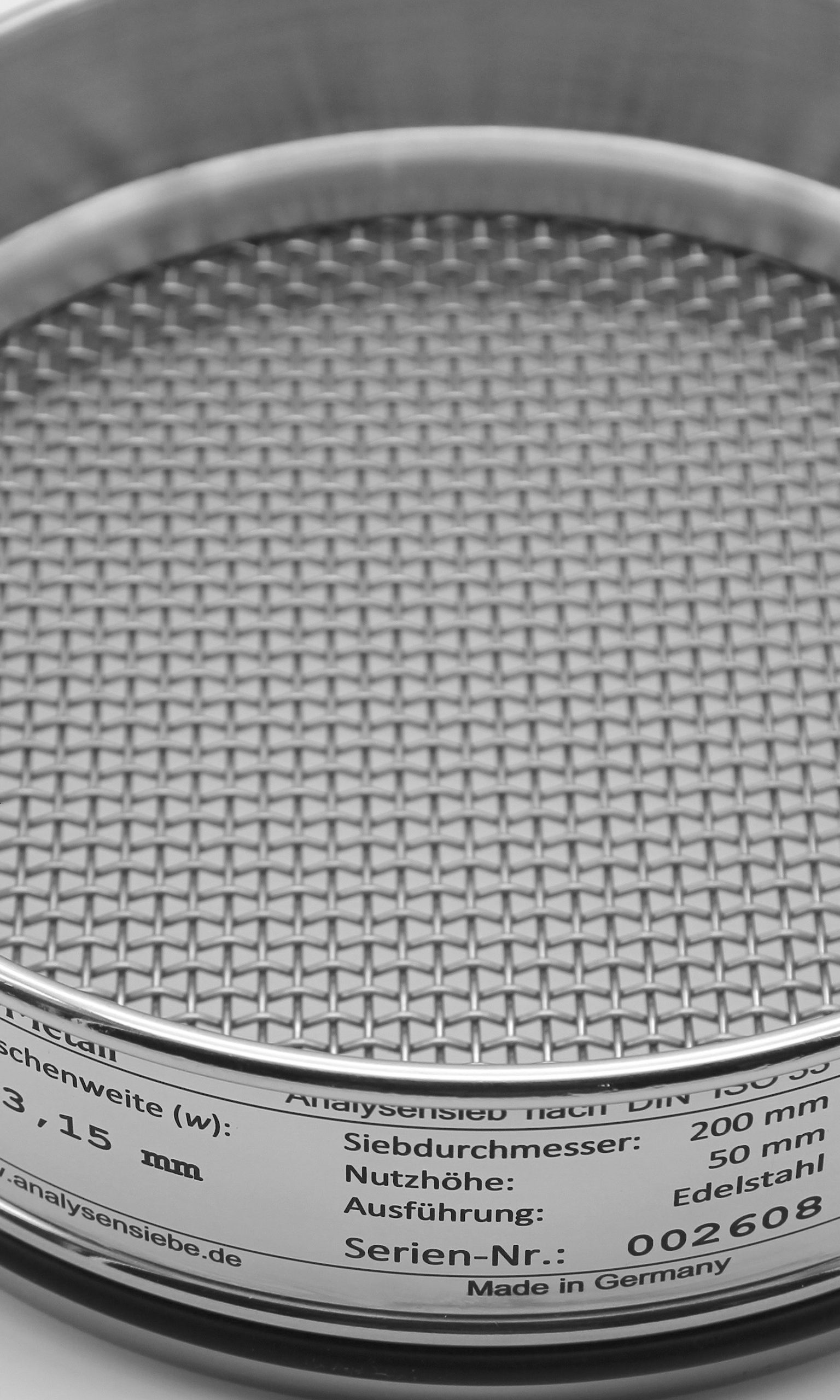

Grain Sieves ISO 5223

As a key part of our product range, we offer all test sieve sizes included in ISO 5223 for the classification of grains / cereals. In compliance with ISO 5223, all Blau-Metall Sieves undergo optical

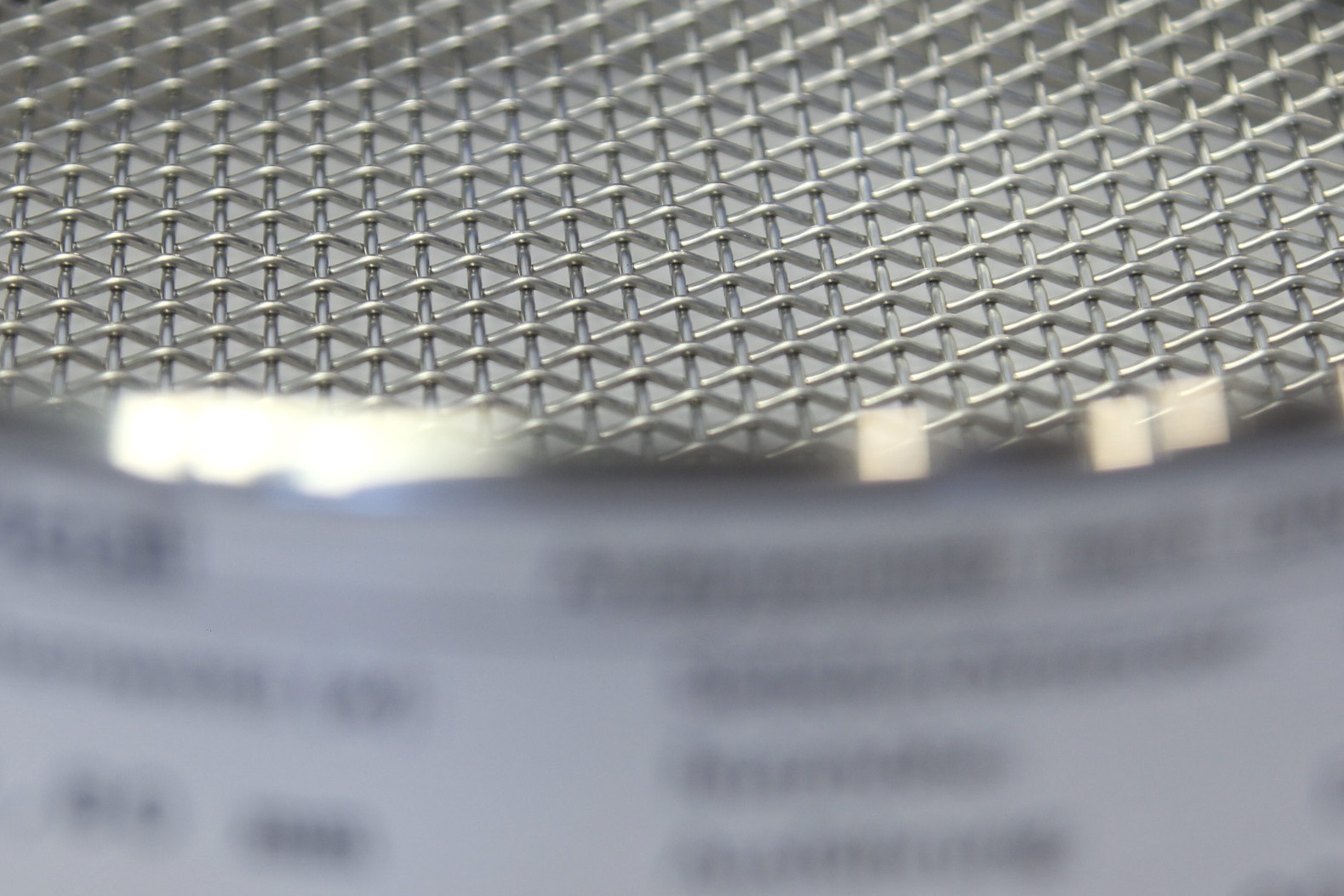

Blau-Metall Made-to-Spec

Blau-Metall offers tailor-made sieves for your specific sieving task: perforated plates with custom-made perforation patterns, tolerances based on current standards or according to customer requirements, detailed documentation.

Test Sieve Certification

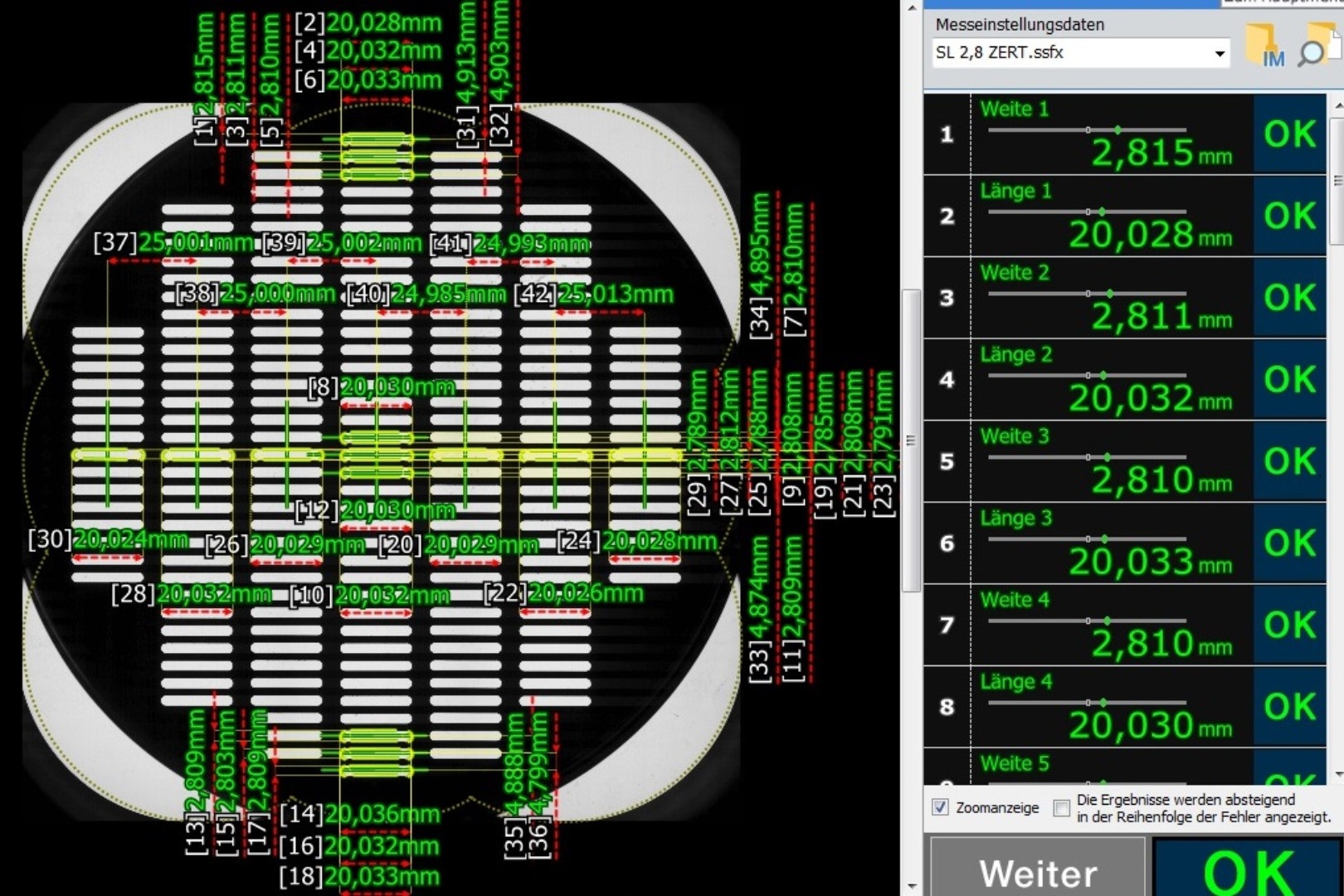

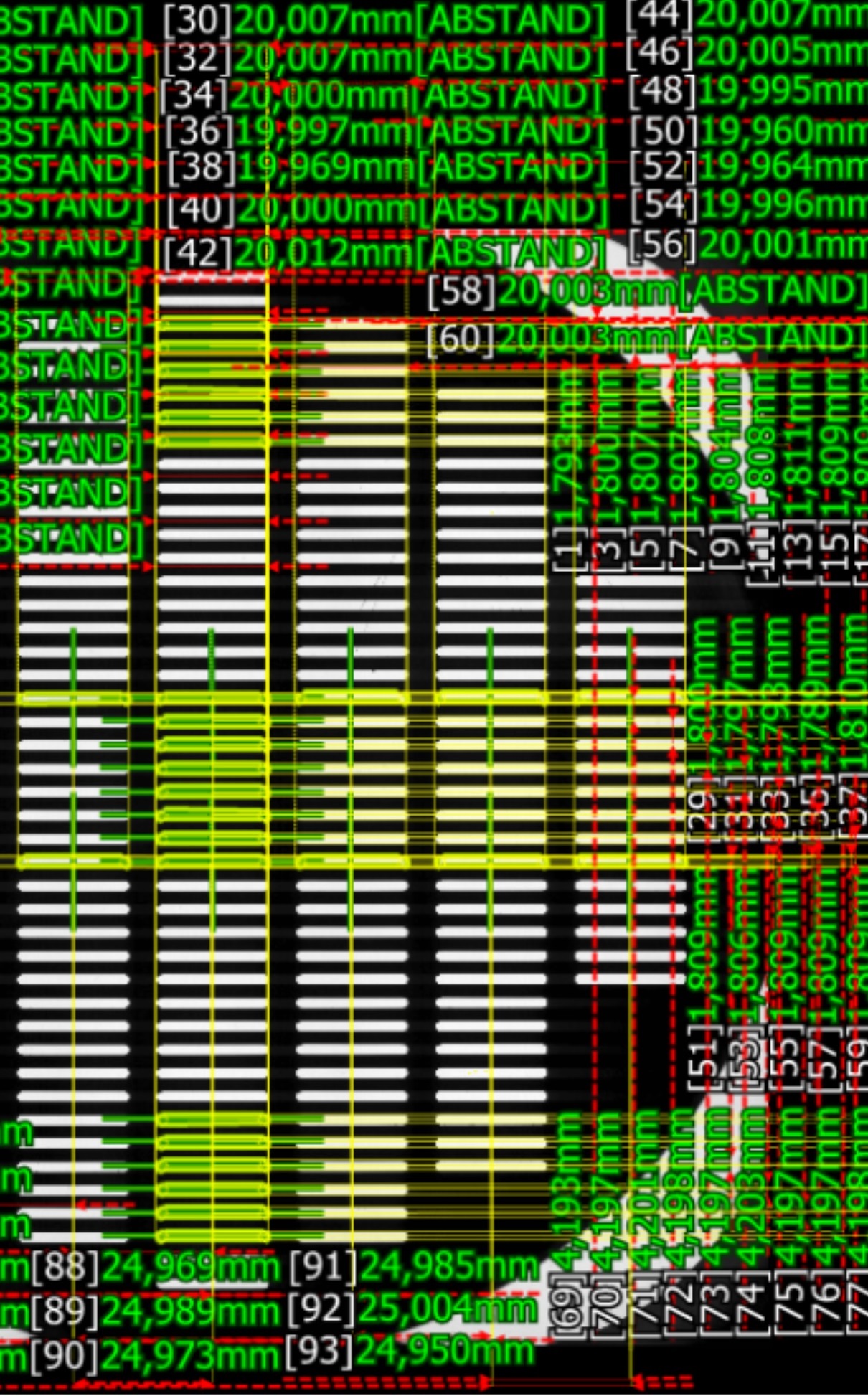

All Blau-Metall test sieves undergo optical measurement in accordance with testing methods outlined in the respective standard. Certification of sieves using modern Image Dimension Measurement Technology ensures highly reliable sieving results.

Detailed Documentation

Every Blau-Metall sieve comes with a certificate of conformity. Inspection and Calibration Certificates according to EN 10204 3.1 can be provided at the request of the customer.

Re-Certification

As measurement instruments, test sieves have to be checked at regular intervals. Blau-Metall offers re-certification services for a variety of national & international standards and provides documentation for every sieve according to EN 10204.

Blau-Metall Laboratory Sieves

Blau-Metall offers a palette of products – including Woven Wire Cloth Test Sieves and test sieves fitted with perforated plates featuring round, square and slotted apertures – suitable for all types of screening tasks: hand sieving, conventional screening analysis of aggregates, dry- and wet-sieving. Our precision-aperture technology and rigorous optical inspections using modern Image Dimension Measurement Systems guarantees our sieves meet the highest criteria of national and international standards such as ISO 3310.

Blau-Metall also offers individual sieve solutions tailored to the unique requirements of your sieving task.

Applications: Particle Size Distribution Analysis, Sample Preparation, Fractionation

Material to be Sieved: Powders, Aggregates, Suspensions, Seeds, etc.

Industrial Areas: Agriculture, Construction (Building & Road Construction), Environmental Technology, Food Industry, Geology, Medicine & Pharma, Metallurgy

Technical Specifications:

Sieve Diameter: 200 mm, 400 mmSieve Depth H1: 32, 50 or 65 mm

Woven Wire Cloth: 30 µm to 11,2 mm (Stainless Steel)

Round Apertures: 0,5 to 125 mm (Stainless Steel)

Square Apertures: 4,0 to 125 mm (Stainless Steel)

Grain Sieves according to ISO 5223

In addition to years of experience, Blau-Metall employs state of the art inspection technology to carry out optical measurements on every sieve we deliver – guaranteeing precise compliance with the standard and enabling highly precise sieving analysis.

Blau-Metall Grain Sieves:

Sieve Diameter: 200 mmSieve Depth H1: 32 mm

Sieve Design: Stainless Steel (Frame, Perforated Plate, Tensioning Ring)

Slotted Hole Sieve Aperture Width: 1,00 to 3,55 mm

Round Hole Sieve Aperture Width: 1,40, 1,80 and 4,50 mm

Norm-Compliance • Certification • Re-Certification

Blau-Metall offers detailed inspection certificates and norm-compliance services for a fully integrated quality assurance at delivery of the sieve as well as full traceability of each and every sieve provided by us. Our optical inspection technology permits complete metrological traceability and compliance with national / international standards.

Norm-Compliance Documentation of Blau-Metall Test Sieves:

Made-to-Spec • Individual Solutions

Test sieves made to measure for all types of application, Tolerances matching or exceeding common sieve standards, Detailed certification of conformity with given tolerances

You are facing a screening task or another analytical problem calling for less common or extravagant sieve dimensions that cannot be found in any of the typical sieve standards? No problem – with our unique Made-to-Spec Service we can realize any perforation pattern as single-piece production or small batches: any perforation pattern, any plate thickness, custom plate materials, any aperture pitch, and tolerances according to customer specification.

Technical Specifications:

Available Sieve Types: Round Apertures (Rg, Rv, RdV), Slotted Apertures (Lg, Lv, Lvc), Square Apertures (Qg, Qv, Qdv), Triangular Apertures, Hexagonal Apertures (Hc), etc.Aperture Width: from 2,00 mm

Standard Tolerance for Aperture Width: ±0,05 mm

Utilizing modern CNC Technology and innovative surface treatment methods, Blau-Metall can deliver ultra-precise perforated plate sieves conforming with the aperture requirements given by our customer. As a flat-rate service with no hidden fees, Blau-Metall Made-to-Spec includes Calibration Certificates 3.1 according to EN 10204 as well as documentation tailored to the customer’s needs up to measurement of every single sieve aperture.

Application-Specific

All Advantages of Blau-Metall Test Sieves

- Stainless steel frame & perforated plate / wire mesh for high stability, corrosion resistance

- Long lifetime and high reliability for all sieving tasks

- Smooth frame surface to eliminate cross-contamination & simplify sieve cleaning

- Very high tension of woven wire mesh even after extended use

- Compatibility with comparable test sieves of other manufacturers

- Compatibility with sieve shakers of all major manufacturers

- Rigorous optical inspection & quality control guarantees norm compliance

- Full traceability & documentation of inspections