SAbrasive blasting is a popular surface treatment process that is often used as a versatile processing method for cleaning or decoating of surfaces, core removal and desanding of cast components, stabilization of surfaces, deburring of workpieces, and preparation of pieces for additional processing steps as well as decorative work including tarnishing and placing structural effects. To realize a varied spectrum of applications, a number of blasting techniques have been developed which differentiate in the blasting agent that is employed, the speed at which the blasting agent is applied, and the medium used to transport the abrasive agent.

SAbrasive blasting is a popular surface treatment process that is often used as a versatile processing method for cleaning or decoating of surfaces, core removal and desanding of cast components, stabilization of surfaces, deburring of workpieces, and preparation of pieces for additional processing steps as well as decorative work including tarnishing and placing structural effects. To realize a varied spectrum of applications, a number of blasting techniques have been developed which differentiate in the blasting agent that is employed, the speed at which the blasting agent is applied, and the medium used to transport the abrasive agent.

The properties of the blasting agent itself are a major factor on which the result of the blasting process depends. A number of different blasting agents have been developed from which can be chosen depending on the requirements of the specific blasting task, also taking into consideration material-scientific and economic criteria. The requirements for quality control testing of blasting agents are defined in the following international standards:

- EN ISO 11125: Preparation of steel substrates before application of paints and related products - Test methods for metallic blast-cleaning abrasives - Part 1: Sampling (ISO 11125-1:2018)

- EN ISO 11127: Preparation of steel substrates before application of paints and related products - Test methods for non-metallic blast-cleaning abrasives - Part 1: Sampling (ISO 11127-1:2011)

Both of the above standards include a dedicated part that defines the instruments and methods to be used for the determination of particle size distribution for both metallic and non-metallic blasting agents as an obligatory quality control process. The mandatory process for the analysis of blasting agents is a traditional sieve analysis employing test sieves of the R20/3, R20 and R40/3 series specified in ISO 565 whereas the aperture sizes are to be chosen dependent on the anticipated grain sizes of the product to be inspected. The technical regulations specify that sieves with a 200-millimeter frame diameter and sieve depths with square apertures are to be employed for the screening analysis. Regular calibration requirements of the sieves by their operators or another party is also required to remain compliant with the above standards.

Both of the above standards include a dedicated part that defines the instruments and methods to be used for the determination of particle size distribution for both metallic and non-metallic blasting agents as an obligatory quality control process. The mandatory process for the analysis of blasting agents is a traditional sieve analysis employing test sieves of the R20/3, R20 and R40/3 series specified in ISO 565 whereas the aperture sizes are to be chosen dependent on the anticipated grain sizes of the product to be inspected. The technical regulations specify that sieves with a 200-millimeter frame diameter and sieve depths with square apertures are to be employed for the screening analysis. Regular calibration requirements of the sieves by their operators or another party is also required to remain compliant with the above standards.

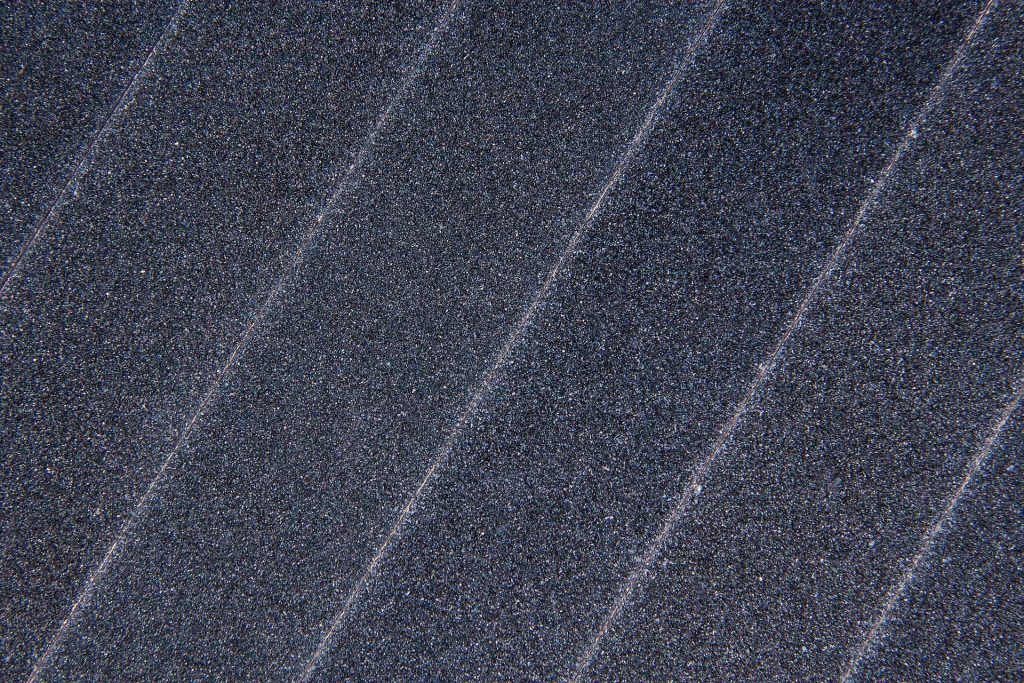

Blau-Metall laboratory test sieves with woven wire cloth in accordance with ISO 3310-1 fulfil the requirements of EN ISO 11125 and 11127. Our sieves guarantee reliable screening results through a robust stainless steel design, precision aperture technology, and an extraordinarily high tension within the wire cloth.

Blau-Metall offers Re-certification services of used test sieves, as required by the standards governing the use of blasting agents, employing our modern digital Image Dimension Measurement systems to ensure sieves remain compliant with the requirements of ISO 3310. Our re-certification services are available for all types of sieves from all manufacturers; we grant discounts of up to 35% for re-certification of Blau-Metall sieves. Additional information regarding Certification & Re-Certification.

Test Sieves for Gradation Analysis of Blasting Agents, ISO 11125 / 11127

Stainless Steel, Diameter 200 mm, Standard Delivery Time: 10 Days

| Article | Standard | Sieve Diameter | Sieve Depth (H1) |

|---|---|---|---|

| Woven Wire Cloth Sieve 2,80 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 2,36 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 2,24 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 2,00 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 1,80 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 1,60 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 1,40 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 1,18 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 1,00 mm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 900 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 850 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 800 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 710 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 630 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 600 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 500 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 400 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 355 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 315 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 250 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 200 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 180 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 160 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 125 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 100 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 90 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 63 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 50 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Collecting Pan | 200 mm | 25 / 50 mm | |

| Sieve Lid | 200 mm | 27 mm |

German Website

German Website