Loading...

Loading...

The Inspection Certificate 3.1 for test sieves with woven wire cloth is issued in a two-page version: Page 1 contains the actual inspection report with all required sieve properties and graphical representation while Page 2 shows all measured parameters to provide full transparency for the protocol on Page 1. All parameters are being acquired according to the measurement methods outlined in ISO 3310-1. An additional appendix showing screenshots of the inspection via Image Dimension Measurement Technology can be provided at the request of the customer.

The Inspection Certificate 3.1 for test sieves with woven wire cloth is issued in a two-page version: Page 1 contains the actual inspection report with all required sieve properties and graphical representation while Page 2 shows all measured parameters to provide full transparency for the protocol on Page 1. All parameters are being acquired according to the measurement methods outlined in ISO 3310-1. An additional appendix showing screenshots of the inspection via Image Dimension Measurement Technology can be provided at the request of the customer.

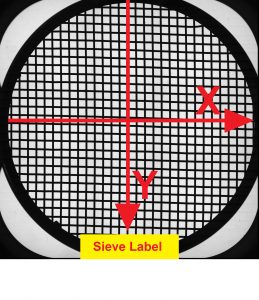

Assignment of Warp- and Weft-Directions: After completion of test sieve production, the directions of the original warp and weft from when the wire cloth was manufactured can no-longer be differentiated in a plain weave mesh. As a standardization measure and comparability of results of subsequent inspections, we take the sieve label as reference point and assign apertures running in Y-direction to Warp and apertures running in X-direction to Weft.

Nomenclature and Abbreviations used in Inspection Certificate:

±Y: Maximum permissible deviation of the arithmetical mean value of the aperture widths from the nominal aperture width (ref. Table 1, ISO 3310-1)

+X: Maximum permissible width of a single aperture (ref. Table 1, DIN ISO 3310-1)

σ0: Maximum permissible standard deviation (ref. Table 1, ISO 3310-1)

Arithmetic Mean Value w̅: Arithmetic mean of aperture widths measured in warp and weft direction

Deviation |±Y|: Deviation of the measured arithmetic mean values w̅ from the nominal sieve opening specified in ISO 3310 (this parameter must be smaller or equal to ≤ (±Y) for the sieve to remain norm-compliant)

Max w: The maximum aperture width measured in warp and weft direction (this parameter must be smaller than w+X (Nominal aperture width + Maximum permissible width of single aperture) for the sieve to remain norm-compliant)

Standard Deviation σs: The standard deviation calculated from the measured parameters shown on Page 2; calculated according to Equations 4 and 5 in ISO 3310-1 (σs must be smaller or equal to ≤ σ

K-Factor: The K-Factor for the given standard deviation. Calculated according to equation 6 ISO 3310-1 for Certification and equation 7 ISO 3310-1 for Calibration.

Arithmetic Mean Value d̅: Arithmetic mean of the wire diameters measured in warp and weft direction (must be within the permissible range for the wire diameter for the sieve to remain norm-compliant, ref. Table 1 ISO 3310)

Deviation Δd̅: Deviation of the mean value d̅ from the given nominal wire diameter for the respective sieve.

ni <(w-Y): Number of apertures smaller than w-Y (Nominal aperture width - Maximum permissible deviation of the arithmetical mean value)

(w-Y)<ni<(w+Y): Number of apertures with widths between w-Y and w+Y , this should be the largest fraction in a norm-compliant sieve

(w+Y)< ni<(w+X): Number of apertures wider than w+Y, but smaller than w+X (wider than desired, but still permissable until reaching a certain fraction)

ni>(w+X): Number of apertures that exceed the maximum permissible width of a single aperture (is this parameter greater than 0, the sieve is to be discarded)

German Website

German Website