For the quality classification of solid biofuels such as Graded Wood Pellets according to Quality Grades EN plus A1, A2, B, sieve analysis is deemed necessary for the determination of fines content which is critical parameters for the safety and quality of wood pellets. The fraction of fines is an obligatory parameter to be determined according to national and international standards, alongside other properties like water content, bulk density, heat value or heavy metal concentration. Requirements for these properties and testing methods to determine them are regulated by ISO 17225 (Solid biofuels - Fuel specifications and classes).

For the quality classification of solid biofuels such as Graded Wood Pellets according to Quality Grades EN plus A1, A2, B, sieve analysis is deemed necessary for the determination of fines content which is critical parameters for the safety and quality of wood pellets. The fraction of fines is an obligatory parameter to be determined according to national and international standards, alongside other properties like water content, bulk density, heat value or heavy metal concentration. Requirements for these properties and testing methods to determine them are regulated by ISO 17225 (Solid biofuels - Fuel specifications and classes).

"The objective of the ISO 17225 series is to provide unambiguous and clear classification principles for solid biofuels and to serve as a tool to enable efficient trading of biofuels and to enable good understanding between seller and buyer as well as a tool for communication with equipment manufacturers. It will also facilitate authority permission procedures and reporting."

Fines content has become an important quality measure for wood pellets and other biofuels, given that excessive fines content can increase the risk for dust explosions and pose a risk when being aspirated by humans. To that end, there are different standards according to which fines content and testing methods are governed: requirements for maximum fines content for different grades of pellets are specified in ISO 17225-2 (Solid biofuels - Fuel specifications and classes - Part 2: Graded wood pellets) while the testing method for the determination of fines is outlined in EN ISO 18846 (Solid biofuels - Determination of fines content in samples of pellets).

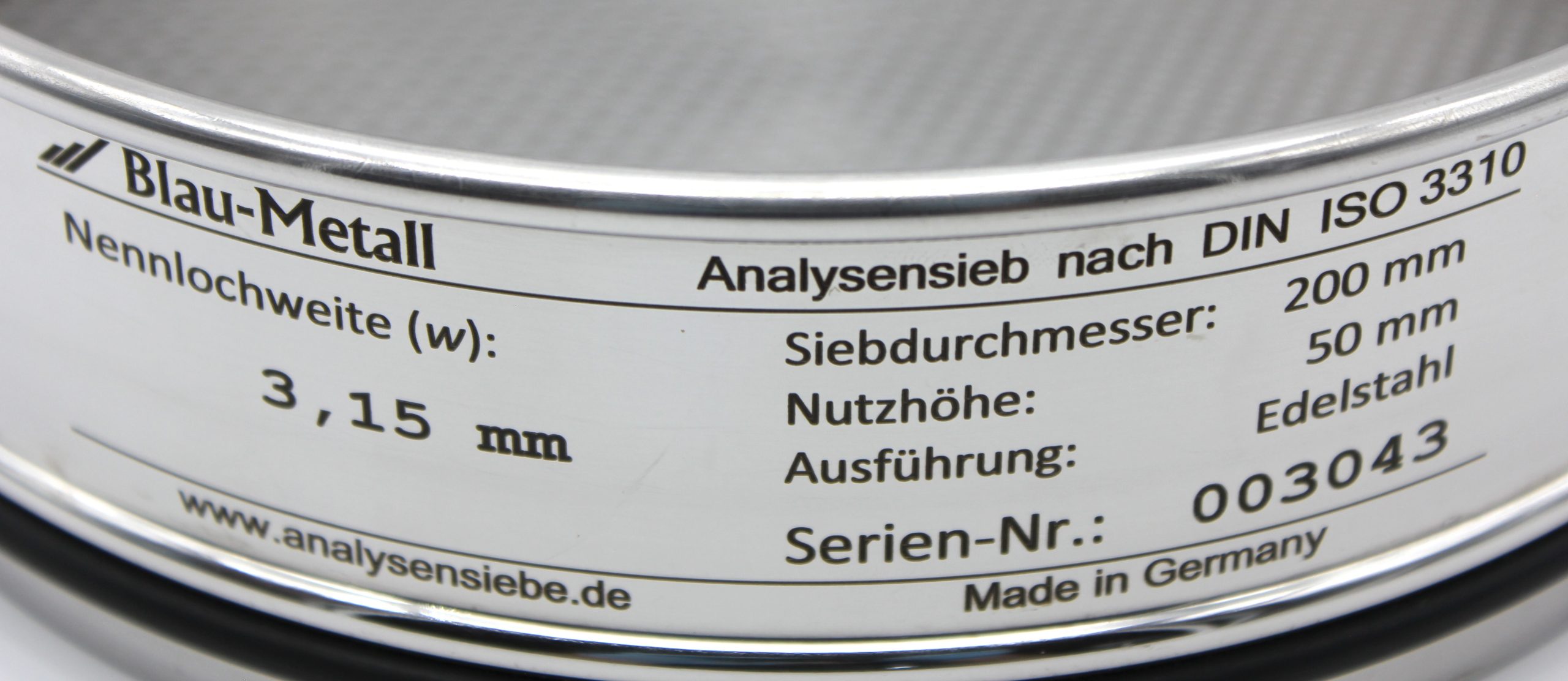

ISO 18846 requires the fines content in wood pellets to be determined via a manual sieve analysis employing a perforated plate sieve with 3,15 mm round apertures, manufactured and certified according to the specifications of ISO 3310-2. While other biofuels can be subjected to automatic / machine sieving, this process was ruled out for pellets because the motion of automatic sieve shakers could cause additional abrasion and so increase the fines content of the sample during the testing process.

ISO 18846 requires the fines content in wood pellets to be determined via a manual sieve analysis employing a perforated plate sieve with 3,15 mm round apertures, manufactured and certified according to the specifications of ISO 3310-2. While other biofuels can be subjected to automatic / machine sieving, this process was ruled out for pellets because the motion of automatic sieve shakers could cause additional abrasion and so increase the fines content of the sample during the testing process.

The manual sieving process for pellets is carried out the determination of the mechanical durability of pellets and to quantify the fines content at the point of portioning the samples / shipment to the end user / packing into sacks. According to EN plus regulations, multiple measurements of fines content may be necessary by the various parties involved in the sale of pellets (manufacturer, merchant, shipment provider).

According to the method described in EN ISO 18846, a pellet sample of sufficient mass shall be weighed before careful delivery onto a perforated plate sieve with 3,15-mm round apertures according to ISO 3310-2. The manual sieving process shall use horizontal back-and-forth motion until the sample has been deemed fully screened. EN ISO 18846 recommends a sieve diameter of 400 mm, though smaller sieve diameters may be chosen for practical reasons as long as the sample volume can move freely across the sieve medium and the sieve is not overloaded.

According to the method described in EN ISO 18846, a pellet sample of sufficient mass shall be weighed before careful delivery onto a perforated plate sieve with 3,15-mm round apertures according to ISO 3310-2. The manual sieving process shall use horizontal back-and-forth motion until the sample has been deemed fully screened. EN ISO 18846 recommends a sieve diameter of 400 mm, though smaller sieve diameters may be chosen for practical reasons as long as the sample volume can move freely across the sieve medium and the sieve is not overloaded.

The material passing through the sieve medium shall be captured in an appropriate collecting pan matching the sieve diameter followed by weighing with a scale of specified accuracy and calculation of the mass proportion of fines with respect to the total sample mass.

Blau-Metall manufactures 3,15 mm round aperture test sieves in accordance with ISO 3310-2, as called for in DIN EN 18846 and provides services for sieve certification and calibration to increase the statistical certainty of pellet quality screening.

| Article | €/Pcs. |

|---|---|

| Ø200 mm Test Sieve ISO 3310-2, 3,15 mm Round Aperture | from 151,00 € |

| Ø300 mm Test Sieve ISO 3310-2, 3,15 mm Round Aperture | 339,00 € |

| Ø400 mm Test Sieve ISO 3310-2, 3,15 mm Round Aperture | 398,00 € |

| Inspection Certificate 3.1 (Certification) | 25,00 € (200 mm), 59,00 € (400 mm) |

| Inspection Certificate 3.1 (Calibration) | 50,00 € (200 mm), 125,00 € (400 mm) |

| Collecting Pan 200 x 25 mm | 43,00 € |

| Collecting Pan 200 x 50 mm | 45,00 € |

| Collecting Pan 300 x 60 mm | 109,00 € |

| Collecting Pan 400 x 70 mm | 115,00 € |

Test Sieves with 3,15 mm Round Apertures are also required by the following Standards:

EN ISO 17827-2:2016-10:Solid biofuels - Determination of particle size distribution for uncompressed fuels - Part 2: Vibrating screen method using sieves with aperture of 3,15 mm and below

EN 15149 (Retracted): Solid biofuels- Determination of particle size distribution - Part 2: Vibrating screen method using sieve apertures of 3,15 mm and below

EN 15210-1 (Retracted): Solid biofuels - Determination of mechanical durability of pellets and briquettes - Part 1: Pellets

Solid biofuels - Particle size distribution of disintegrated pellets

German Website

German Website