The exact determination of mechanical properties of soils or building ground is a fundamental component of the engineering and construction sector. The accurate determination of grain size distribution in soils is of particular importance as it provides instrumental information regarding the static characteristics of a given soil and, with that, its suitability for a planned building project.

The exact determination of mechanical properties of soils or building ground is a fundamental component of the engineering and construction sector. The accurate determination of grain size distribution in soils is of particular importance as it provides instrumental information regarding the static characteristics of a given soil and, with that, its suitability for a planned building project.

The determination of a soil’s grain size distribution by means of gradating testing with test sieves builds the foundation for the determination of a number of relevant parameters such as water permeability, load-bearing capacity, sensitivity to frost, erosion susceptibility and several other critical properties that are of critical value to the classification of soil stability for building projects of any kind. Soil-mechanical analysis is also seen as a bridge between the actual building ground and the input parameters for numerical and analytical simulations yielding the precise properties of the soil.

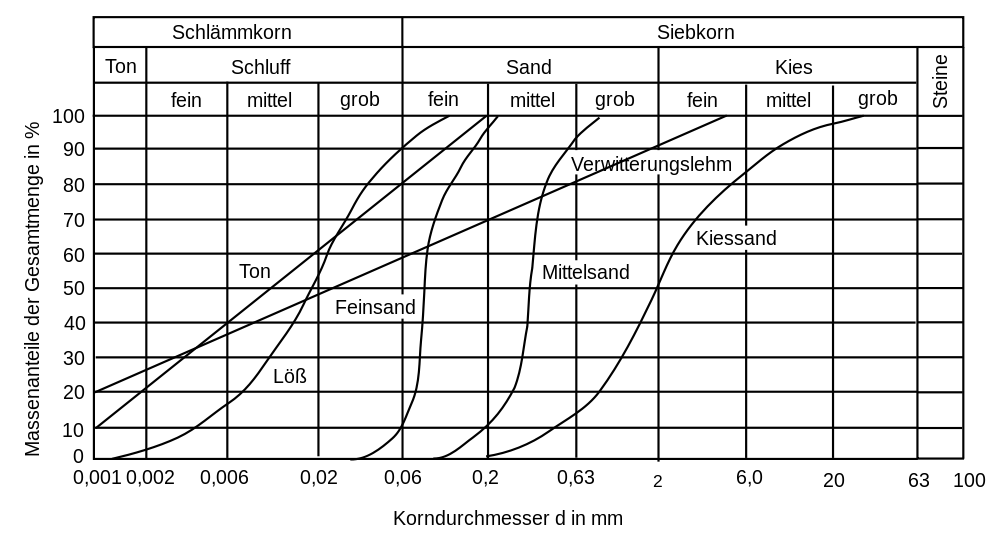

The goal of gradation testing by means by laboratory sieve analysis is the determination of the distribution of grain sizes by mass percentage (xmi) for each grain fraction: clay, silt, sand, gravel & cobble whereby the determination of fines within the soil is given particular attention since that fraction has a great impact on the geotechnical and geohydraulical properties of the soil.

A correct and reliable grain size distribution measurement in building grounds is of critical importance for public safety since it builds the foundation for the structural safety of the building project. For that reason, obligatory methods and instruments have been set in place by different regulations that are to be employed for the determination of grain size distribution in building. For coarse soils, grain size distribution is determination via conventional gradation analysis using a sieve column in laboratory conditions; analysis of mixed- and fine-soils is completed by a combination of gradation testing and sedimentation.

A correct and reliable grain size distribution measurement in building grounds is of critical importance for public safety since it builds the foundation for the structural safety of the building project. For that reason, obligatory methods and instruments have been set in place by different regulations that are to be employed for the determination of grain size distribution in building. For coarse soils, grain size distribution is determination via conventional gradation analysis using a sieve column in laboratory conditions; analysis of mixed- and fine-soils is completed by a combination of gradation testing and sedimentation.

The methods and instrumental requirements for these types of laboratory procedures are set by the international standard EN ISO 17892-4 (Geotechnical investigation and testing - Laboratory testing of soil - Part 4: Determination of particle size distribution). This relatively new standard replaces the previously used DIN 18123 (Soil, investigation and testing - Determination of grain-size distribution). The classification and technical description of soils / building grounds is regulated by ISO 14688 (Geotechnical investigation and testing - Identification and classification of soil - Part 1: Identification and description). Instruments and methods for gradation analysis is also outlined in ASTM C 136 and AASHTO T 27.

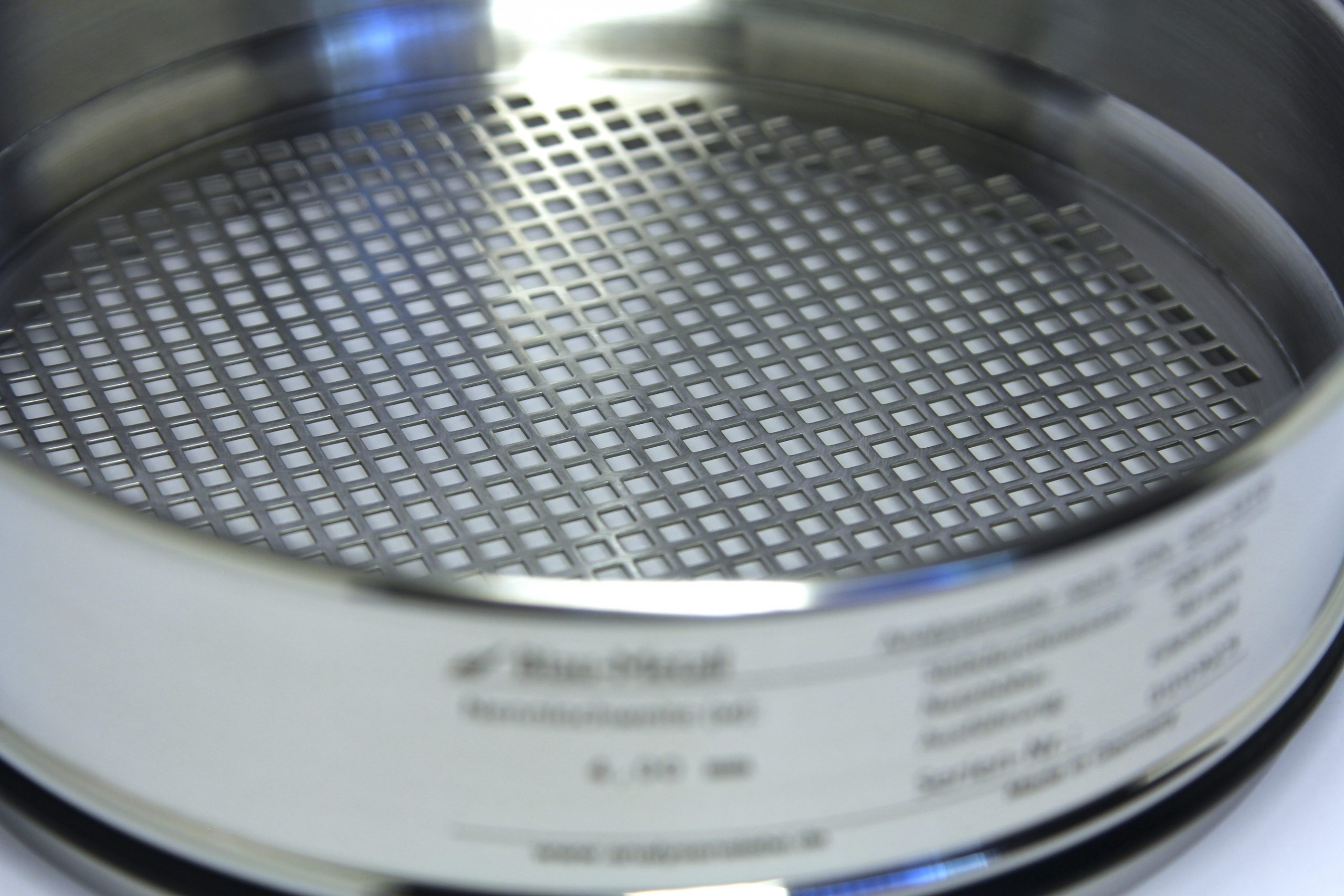

For the determination of grain size distribution in accordance with ISO 17892, a set of laboratory test sieves compliant with ISO 3310-1 and ISO 3310-2 as well as compatible collecting pans are to be used, whereas the aperture sizes are to be chosen in a manner appropriate for the soil that is to be analyzed in order to ensure that any irregularities in the grain-size distribution curve can be detected.

For the determination of grain size distribution in accordance with ISO 17892, a set of laboratory test sieves compliant with ISO 3310-1 and ISO 3310-2 as well as compatible collecting pans are to be used, whereas the aperture sizes are to be chosen in a manner appropriate for the soil that is to be analyzed in order to ensure that any irregularities in the grain-size distribution curve can be detected.

Blau-Metall offers all commonly used woven wire cloth and perforated plate sieves included in ISO 3310-1/2 as a complete solution for all requirements outlined in ISO 17892. High statistical certainty of gradation analysis is ensured through rigorous optical inspection of every Blau-Metall sieve prior to shipment to the customer (upon customer request, we can issue Inspection Certificates for our sieves or carry out Calibration Inspections for additional inspection data).

Given the immense importance of grain size distribution as a fundamental soil-mechanical parameter, it is recommended to pay particular attention to the compliance with the required standard when purchasing test sieves and to adhere to the recommended intervals for the re-certification of used sieves (ref. MessG, ISO 9001, ISO 3310).

Blau-Metall provides Re-Certification Services for used test sieves in accordance with ISO 3310 and delivers to the customer full documentation of inspection results. Re-certification is offered for sieves by all manufacturers; we grant a discount of up to 35% for re-certification of Blau-Metall sieves.

Test Sieves for Gradation Analysis according to ISO 17892-4 / DIN 18123

Delivery Time: ~10 Days

| Article | Standard | Sieve Diameter |

|---|---|---|

| Test Sieve Square Aperture 63,0 mm | DIN ISO 3310-2 | 200, 300, 400 mm |

| Test Sieve Square Aperture 31,5 mm | DIN ISO 3310-2 | 200, 300, 400 mm |

| Test Sieve Square Aperture 16,0 mm | DIN ISO 3310-2 | 200, 300, 400 mm |

| Test Sieve Square Aperture 8,0 mm | DIN ISO 3310-2 | 200, 300, 400 mm |

| Test Sieve Square Aperture 4,0 mm | DIN ISO 3310-2 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 2,0 mm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 1,0 mm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 500 µm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 250 µm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 125 µm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Test Sieve Woven Wire Cloth 63 µm | DIN ISO 3310-1 | 200, 300, 400 mm |

| Collecting Pan | 200, 300, 400 mm |

Dry Sieving Procedure for Gradation Testing:

A column of at least seven test sieves is arranged according to the suspected size distribution properties of the soil that is to be analyzed to ensure any irregularities in grain size distribution can be detected. A representative weighed sample is delivered to the top sieve which as the largest aperture size (each lower sieve in the column has smaller opening than the one above; at the bottom sits a suitable collecting pan). Through the use of a sieve shaker, the sample is set into motion in a way specified in the applicable standard. After a predetermined amount of time has expired, the material left on each sieve is weighed and converted into mass-percentages of the total mass of the sample. The obtained values are depicted as a half-logarithmic cumulative curve to yield the characteristic grain size distribution diagram for the given soil which builds the basis for additional analysis and numerical simulations.

German Website

German Website