Test Sieves for Tobacco in accordance with CORESTA Guidelines

The global tobacco industry has grown to an estimated total sales volume in excess of $ 900 million in 2025 and is expected to approach the trillion-Dollar mark by the end of the current decade. A number of quality metrics have been developed for tobacco products – from the initial processing stages to the finished end product – in order to allow for a clear communication between buyers and sellers when assessing the quality of tobacco and setting its price.

The global tobacco industry has grown to an estimated total sales volume in excess of $ 900 million in 2025 and is expected to approach the trillion-Dollar mark by the end of the current decade. A number of quality metrics have been developed for tobacco products – from the initial processing stages to the finished end product – in order to allow for a clear communication between buyers and sellers when assessing the quality of tobacco and setting its price.

Certain types of tobacco are harvested as whole plants – including the plant stem – and then subjected to the drying process. This way, the tobacco leaves can keep drawing nutrients from the stems which preservers their sugar content and aroma in order to yield the desired flavor profile of the finished product. More traditional varieties of tobacco have their leaves stripped directly at harvest to then be dried and undergo further processing. Regardless of the harvesting method, an important step in the processing of tobacco is separating the desired parts of the plant from those that are to be discarded.

One key quality metric of tobacco is the quantity of plant stems, leafstalks, leaf veins and other plant parts that are not the desired lamina strips of the actual leaf tissue in between the leafstalks. The lamina strips are obtained by means of threshing or hand stripping of leaves in which the desired tissue is separated from the unwanted stems. Naturally, as no manual or automatic process is perfect, a certain mass fraction of stems will end up in the separated lamina strips.

In order to be able to classify tobacco into quality categories, determining the size distribution of leaf strips and quantifying the proportion of stems are of particular importance. The methods for obtaining these critical quality markers have been standardized under the guidelines issued by CORESTA (Cooperation Centre for Scientific Research Relative to Tobacco) as well as different international standards, e.g. ISO 12194 (Threshed tobacco - Determination of residual stem content).

The determination of lamina strip particle size is described as a standardized method in CORESTA Recommended Method (CRM) No. 16 which calls for a specialized testing apparatus comprising a conveyor belt which feeds the material to four vibrating sieving trays and a fines collecting pan – all mounted in a robust frame. The four sieve trays are to be fitted with woven wire cloth compliant with ASTM E 11 and descending opening sizes of 1,0, 0,5, 0,25 and 0,0937 in. (25, 12,5, 6,3 and 2,36 mm).

After sampling is complete, particles in the five collecting bins (four for the sieves and one at the bottom to catch the fines) are weighed, and a particle size distribution is calculated from the mass of lamina strip particles in each collecting bin (ref. ISO 12194 & CRM No. 16).

A different method applies to the determination of stem content within lamina strips and is defined in CRM No. 17 which requires a representative test sample of a lamina batch to be prepared by a small-scale threshing apparatus before being analyzed by sieving. After weighing of the initial sample, the material is spread evenly onto a conveyor and then fed into the thresher at a uniform rate. After threshing, the material goes through a pneumatic separation process – being transported into a separating tower which employs a controlled flow of air with a defined velocity (dependent on the type of tobacco) to separate the lighter from the heavier parts.

The light lamina is discharged into a bin while the heavies are returned to the thresher for re-threshing. After a set amount of time (typically 4 minutes), the remaining heavies are automatically discharged into a container for weighing and further analysis.

The fraction of heavies (containing stems, stalks, veiny leaves, and potentially foreign materials) is then subjected to sieve analysis. CRM No. 17 calls for the use of a special tapping-type sieve shaker (e.g. WS Tyler Ro-Tap or Retsch AS 200 TAP) that subjects the sample material to a circular sieving motion assisted by a hammer that taps the stacked sieves at specific intervals to coerce the material through the sieve openings and yield complete and repeatable sieving results.

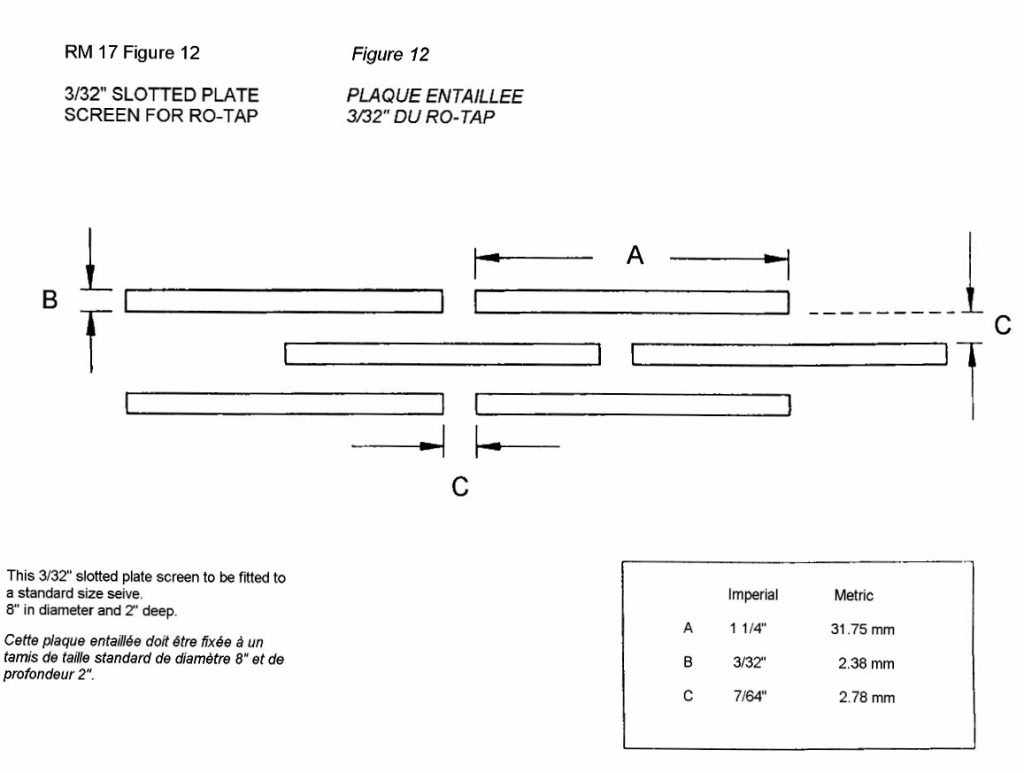

Three sieves and a collecting pan are to be used for the analysis with the stacked topped by a specialized perforated plate sieve referred to as 3/32“ Slotted Plate. The two lower sieves are standard woven wire cloth test sieves with opening sizes of 2.8 mm (U.S. No. 7) and 1.7 mm (No. 12). After sieving the four fractions are weighed and results plotted as follows: the fraction of material retained by the 3/32“ Slotted Plate is defined as stem material, the combined fractions retained by the wire cloth sieves as Stem less Fibre, and finally the material collected in the pan as Fibre Stem.

Three sieves and a collecting pan are to be used for the analysis with the stacked topped by a specialized perforated plate sieve referred to as 3/32“ Slotted Plate. The two lower sieves are standard woven wire cloth test sieves with opening sizes of 2.8 mm (U.S. No. 7) and 1.7 mm (No. 12). After sieving the four fractions are weighed and results plotted as follows: the fraction of material retained by the 3/32“ Slotted Plate is defined as stem material, the combined fractions retained by the wire cloth sieves as Stem less Fibre, and finally the material collected in the pan as Fibre Stem.

Depending on the variety of tobacco and the testing methods that are to be applied, the sieve opening sizes may be adjusted with two additional slotted plates (No. 7 and No. 12) also being frequently used for this type of analysis.

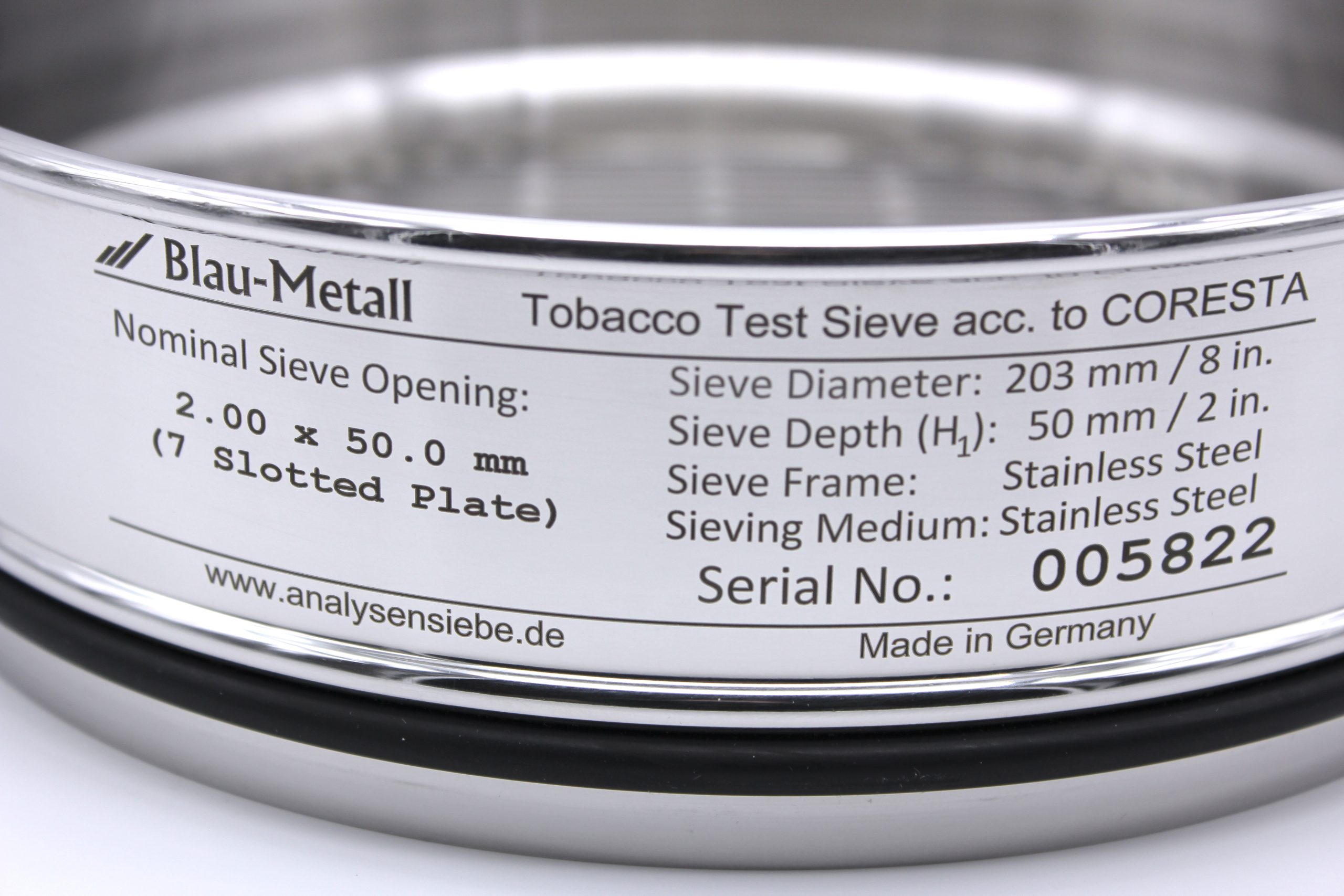

Blau-Metall manufactures specialized test sieves for tobacco in accordance with CORESTA guidelines, employing an all-stainless steel design that provides a long lifetime of the sieve and also ensures tolerances are maintained over an extended period of time. We can offer CORESTA-spec sieves with a diameter of 200 mm or 203 mm / 8 in. to fit in existing sieve stacks and a variety of sieve shakers. As with all Blau-Metall sieves, out tobacco sieves undergo a rigorous optical inspection process to verify all tolerance requirements are fulfilled. Each sieve has a tamper-proof 3D laser label and an individual serial number for full traceability of the sieve. The laser label is available in German or English language; sieves are delivered with a certificate of compliance 2.1 (EN 10204) and can also be outfitted with a detailed test report showing the results of the optical inspection.

Blau-Metall Tobacco Sieves

Delivery Time: approx. 10 Days

| Article | Standard | Sieve Diameter |

|---|---|---|

| Slotted Test Sieve: 1,70 x 50,0 mm (12 Slotted Plate) | CORESTA / Tolerances | 200 mm, 203 mm / 8" |

| Slotted Test Sieve: 2,00 x 50,0 mm (7 Slotted Plate) | CORESTA / Tolerances | 200 mm, 203 mm / 8" |

| Slotted Test Sieve: 2,38 x 31,75 mm (3/32" Slotted Plate) | CORESTA CRM No. 17 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 630 µm | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 1,00 mm (No. 18) | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 1,70 mm (No. 12) | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 2,00 mm (No. 10) | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 2,36 mm (No. 8) | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

| Woven Wire Cloth Test Sieve, Nominal Opening: 2,80 mm (No. 7) | ISO 3310-1 / ASTM E 11 | 200 mm, 203 mm / 8" |

Specifications: Tobacco Sieves with Slotted Plates

| General Specifications | ||

| Test Sieve Frame: | Stainless Steel, 1.4301 | |

| Perforated Plate: | Stainless Steel, 1.4301 | |

| Internal Tensioning Ring: | Stainless Steel, 1.4301 | |

| External Sealant Ring: | Standard: NBR 70 | |

| Optional: FPM 75 | ||

| Internal Solder Joints: | Standard: 60% Sn, 40% Pb | |

| Optional: 99.9% Sn (Pharmaceutical/Food industry) | ||

| Nominal Sieve Diameter: | 200 mm | 203 mm / 8 in. |

| Internal Sieve Diameter (D1): | 199.5 mm | 202.5 mm |

| External Sieve Diameter (max.): | 210 mm | 213 mm |

| External Sieve Diameter (D2): | 199 mm | 202 mm |

| Sieve Depth (H1): | 50 mm | 50 mm / 2 in. |

| Depth (H2), Total Frame Height: | 65 mm | 65.5 mm |

| Frame Wall Thickness: | 0.8 mm | 0.7-0.8 mm |

| Perforated Plate Thickness: | 1.5 mm | 1.5 mm |

| Compatible with Ro-Tap RX-29: | Yes | Yes |

| Collecting Pan (Optional): | 200 x 50 / 200 x 25 mm | 203 x 50 mm |

| Sieve Weight: | 0.50 to 0.65 kg | |

| External Sealant Ring: | 185 x 6.0 mm | |

| Perforation Patterns: | Slotted / Rectangular Openings, Staggered Rows | |

| Operating Temperature: | Standard: -30 to +80 °C | |

| Optional: -15 to +200 °C (FPM & 99.9% Sn) | ||

| Chemical Resistance: | Standard: Limited | |

| Optional: resistant to corrosive acids & bases | ||

| Additional Features: | Tamper-proof 3D Laser Label | |

| Upper safety edge for easy handling | ||

| Documentation: | Certificate of Compliance 2.1 (EN 10204) | |

| Optional: Inspection Certificate 3.1 (EN 10204) | ||

| Language of Sieve Label: | English, German | |

| Language of Documentation: | English, German | |

| Variants & Tolerances | ||

| 12 Slotted Plate | ||

| Slot Width [B]: | 1.70 ± 0.08 mm | |

| Slot Length [A]: | 50.0 ± 0.50 mm | |

| Bridge Width: | 1.70 x 1.70 mm or 2.30 x 4.00 mm (B x A) | |

| 7 Slotted Plate | ||

| Slot Width [B]: | 2.00 ± 0.10 mm | |

| Slot Length [A]: | 50.0 ± 0.50 mm | |

| Bridge Width: | 2.00 x 2.00 mm or 2.00 x 4.00 mm (B x A) | |

| 3/32" Slotted Plate | ||

| Slot Width [B]: | 2.38 ± 0.10 mm | |

| Slot Length [A]: | 31.75 ± 0.20 mm | |

| Bridge Width [C]: | 2.78 ± 0.10 mm | |

| Standard: | CORESTA Recommended Method No. 17 | |

Technical Standards for Tobacco Test Sieves:

CORESTA Recommended Method N° 16 - Lamina Strip Particle Size Determination: https://www.coresta.org/lamina-strip-particle-size-determination-29147.html

CORESTA Recommended Method N° 17 - Stem Content of Lamina Strips: https://www.coresta.org/stem-content-lamina-strips-29148.html

ISO 12194:1995(en) - Leaf tobacco — Determination of strip particle size: https://www.iso.org/obp/ui/es/#iso:std:iso:12194:ed-1:v1:en

ACCEPT Privacy Policy

German Website

German Website