Grain Test Sieves manufactured in accordance with applicable national and international standards are a key component of worldwide grain and cereal trade to provide a reliable means of quality classification in grain quantities of any size. The Blau-Metall sieve portfolio builds on nearly 30 years of experience in the production of robust and highly-precise grain sieves across international ISO standards, European standards, the U.S. Code of Federal Regulations / Department of Agriculture requirements and a variety of national requirements to provide our customers with a complete solution for all grain sieving tasks across all markets.

Grain Test Sieves manufactured in accordance with applicable national and international standards are a key component of worldwide grain and cereal trade to provide a reliable means of quality classification in grain quantities of any size. The Blau-Metall sieve portfolio builds on nearly 30 years of experience in the production of robust and highly-precise grain sieves across international ISO standards, European standards, the U.S. Code of Federal Regulations / Department of Agriculture requirements and a variety of national requirements to provide our customers with a complete solution for all grain sieving tasks across all markets.

Grain analysis using laboratory test sieves has become the obligatory classification method for the quality of grain in the majority of grain-producing nations and is also required by Government Intervention Boards. Blau-Metall offers all sieve sizes included in the major national and international standards such as ISO 5223 as well as sieving accessories to deliver an integrated solution for all standard grain sieving requirements. Additionally, Blau-Metall offers non-standard and custom-made sieves for specialty sieving needs that may arise from new developments in crop production and processing.

Full Compliance

Blau-Metall test sieves stand out for their particularly robust design and their high precision perforated plate achieved through a production process perfected over nearly three decades and a rigorous quality control program that includes multiple stages of optical measurements on each and every sieve we deliver. The sieves consist of high-stability stainless steel frames with smooth upper edges for easy handling and precision-aperture perforated plates made from corrosion-resistant stainless steel, both joined by a stainless-steel tensioning ring and a pair of robust solder joints that form a complete seal that will stay in place over an extended period.

Full Compliance

Blau-Metall test sieves stand out for their particularly robust design and their high precision perforated plate achieved through a production process perfected over nearly three decades and a rigorous quality control program that includes multiple stages of optical measurements on each and every sieve we deliver. The sieves consist of high-stability stainless steel frames with smooth upper edges for easy handling and precision-aperture perforated plates made from corrosion-resistant stainless steel, both joined by a stainless-steel tensioning ring and a pair of robust solder joints that form a complete seal that will stay in place over an extended period. Blau-Metall grain test sieves are compatible with quality sieves of other sieve manufacturers and can be used on sieve shakers and sieve machines of all major suppliers. Given their light weight and handy dimensions, the sieves are also ideally suited for on-site analysis and hand-sieving of grain samples. Our construction methodology with ease of use in mind enables a simple cleaning process for our sieves. With their fully sealed and corrosion- and temperature-resistant design, Blau-Metall sieves can deliver reliable and repeatable sieving results over a period of many years – a stark contrast to comparable sieves with aluminum or galvanized steel components.

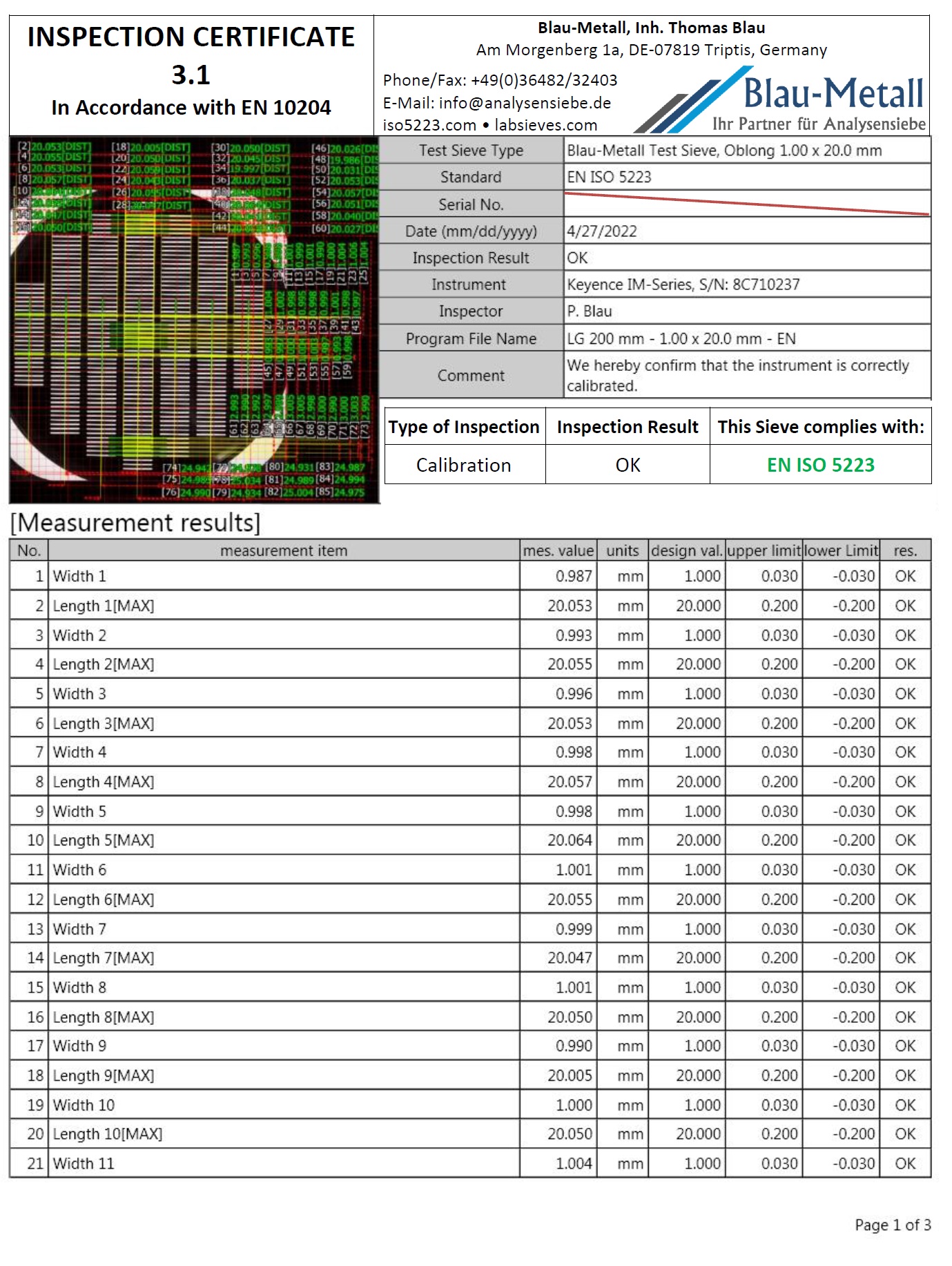

Through a fully transparent quality control process using modern digital measurement technology, we can guarantee an outstanding quality of our Blau-Metall grain sieves and full compliance with the tolerances specified in the applicable national or international standard such as ISO 5223, ISO 3310-2, ASTM E323 and their national equivalents. A tamper-proof laser engraving on every sieve allows for full-traceability through every sieve’s unique serial number. Prior to delivery, each and every sieve undergoes optical inspection and is shipped with a Certificate of Compliance with the Standard (EN 10204 2.1). All test records are stored by Blau-Metall for later reference.

Test Sieves ISO 5223 - Product Highlights

✔ High-Precision Aperture compliant with the Tolerances and Reduced Tolerances of all applicable Standards

✔ Robust Construction: All Stainless-Steel components, Weathering-Resistant & fully sealed joints

✔ Made for durability & long lifetime with consistent and repeatable sieving results

✔ Compatible with sieves & sieve shakers of all major manufacturers

✔ Smooth frame surface to eliminate cross-contamination & simplify sieve cleaning

✔ Increased confidence in sieving results through fully transparent inspection documentation

✔ Inspection Certificate 3.1 included with every sieve

✔ Fully traceability through tamper-proof laser-engraving and extended record-keeping

Technical Specifications

| Overview |

|

| Sieve Sizes |

200 x 32 mm / 200 x 50 mm |

| Sieve Frame |

Stainless Steel |

| Sieve Medium |

Stainless Steel Perforated Plate |

| Standard | EN ISO 5223:2016 |

| Application |

|

- Frame: Stainless Steel 1.4301

- Sieve medium: Stainless Steel 1.4301

- Aperture Width: from 1.00 mm

- Sieve Depth (H1): 32 or 50 mm

- Perforated Area: ø185 mm (unperforated margin)

- Perf. Pattern: Oblong / Round

- Food-grade / temperature-resistant version available

- Incl. Certificate of Compliance, Test Sieve Record Card

PDF Downloads:

- Data Sheet: 200 x 32 mm Test Sieves

- Data Sheet: 200 x 50 mm Test Sieves

- Specs & Prices: 200 mm Oblong Test Sieves

- Specs & Prices: 200 mm Round Test Sieves

Available Sieves

| Aperture Length (w2) | 20,00 mm | ||||||||||||||

| Aperture Width (w1) |

|

||||||||||||||

| Nominal Sieve Opening |

|

|||

* The plate thickness for the 1,00 mm Sieve is 0,8 mm as required by the Federal Office for Agriculture and Food instead of 0,5 mm specified in EN ISO 5223. Plates with 0,5 mm thickness available on request.

Specifications & Tolerances

| Sieve Type | Aperture Size | Tolerances | Pitch | Plate (t) | ⌀ Perf. Area | Standard |

|---|---|---|---|---|---|---|

| Oblong | 1,00 x 20,0 mm | ±0,03 x ±0,2 | 3,00 x 25,0 | 0,8 mm* | 185 mm | EN ISO 5223 |

| Oblong | 1,50 x 20,0 mm | ±0,04 x ±0,2 | 4,00 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 1,60 x 20,0 mm | ±0,04 x ±0,2 | 4,00 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 1,70 x 20,0 mm | ±0,04 x ±0,2 | 4,00 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 1,80 x 20,0 mm | ±0,04 x ±0,2 | 4,20 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 1,90 x 20,0 mm | ±0,04 x ±0,2 | 4,30 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 2,00 x 20,0 mm | ±0,04 x ±0,2 | 4,50 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 2,20 x 20,0 mm | ±0,05 x ±0,2 | 4,90 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 2,25 x 20,0 mm | ±0,05 x ±0,2 | 4,90 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 2,50 x 20,0 mm | ±0,05 x ±0,2 | 4,90 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 2,80 x 20,0 mm | ±0,05 x ±0,2 | 4,90 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 3,50 x 20,0 mm | ±0,06 x ±0,2 | 6,80 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Oblong | 3,55 x 20,0 mm | ±0,06 x ±0,2 | 6,80 x 25,0 | 0,8 mm | 185 mm | EN ISO 5223 |

| Round | 1,40 mm | ±0,08 | 2,60 mm | 0,8 mm | 185 mm | EN ISO 5223 |

| Round | 1,80 mm | ±0,08 | 3,10 mm | 0,8 mm | 185 mm | EN ISO 5223 |

| Round | 4,50 mm | ±0,14 | 6,30 mm | 0,8 mm | 185 mm | EN ISO 5223 |

- Additional Oblong Test Sieves from 0.50 to 10.0 mm: Specifications - Perforated Plate Sieves (Oblong Apertures)

- Additional Round Test Sieves from 0.50 to 125.0 mm: Specifications - Perforated Plate Sieves (Round Apertures)

- Ordering ISO 5223 Test Sieves: Our International Online Store iso5223.com

Accessories for Test Sieves EN ISO 5223, ø 200

| Item | €/Pcs. |

|---|---|

| Test Sieve Lid, 200 x 27 mm | 45,00 |

| Collecting Pan 200 x 25 mm, Stainless Steel | 43,00 |

| Collecting Pan 200 x 50 mm, Stainless Steel | 45,00 |

| Intermediate Pan 200 x 32 mm | 61,00 |

| Intermediate Pan 200 x 50 mm | 63,00 |

| Intermediate Ring 200 x 32 mm (Frame without Sieve Medium) | 43,00 |

| Intermediate Ring 200 x 50 mm (Frame without Sieve Medium) | 45,00 |

Documentation of Norm Compliance of Test Sieves

For many of their applications, laboratory test sieves are classified as measurement instruments and, depending on national and international regulations, have to be inspected by their manufacturer prior to shipment. Blau-Metall complies with these regulations as every single sieve we deliver has undergone optical inspection according to the standard with which the sieve complies. Operators of test sieves are also obligated to re-certify sieves at regular intervals if they are being used as measurement instruments under applicable statutory regulations. Blau-Metall offers cost-efficient re-certification services with fast turnarounds and complete documentation made available to the customer.

For many of their applications, laboratory test sieves are classified as measurement instruments and, depending on national and international regulations, have to be inspected by their manufacturer prior to shipment. Blau-Metall complies with these regulations as every single sieve we deliver has undergone optical inspection according to the standard with which the sieve complies. Operators of test sieves are also obligated to re-certify sieves at regular intervals if they are being used as measurement instruments under applicable statutory regulations. Blau-Metall offers cost-efficient re-certification services with fast turnarounds and complete documentation made available to the customer.Inspection Documents According to EN 10204

Certificate of Compliance with the Standard / Certificate of Compliance with Tolerances For every Blau-Metall test sieve, we issue a free Certificate of Compliance 2.1 to attest that the sieve was manufactured according to the specified standard or tolerances and has passed optical inspections as required by the respective standard. Additionally, a Test Sieve Record Card is issued for every Blau-Metall sieve to keep track of inspections carried out for that specific sieve.

Certificate of Inspection 3.1 / Certificate of Calibration 3.1

Upon customer request, we can deliver test sieves with an Inspection Certificate that includes all results obtained during optical inspection of the sieve to demonstrate its norm-compliance and increase confidence in the results of sieve analyses carried out with our products. Optionally, the inspection process can be carried out as a calibration in which at least three times as many apertures are measured than are required for the conventional certification according to ISO 3310 / EN ISO 5223 or their ASTM equivalents.

Inspection results for each sieve we deliver are saved in our records for at least one year so that Inspection Certificates can be ordered by our customers after the fact, should they be required.

For additional information, refer to our pages on Norm-Conformity & Certification as well as our Re-Certification Service

German Website

German Website