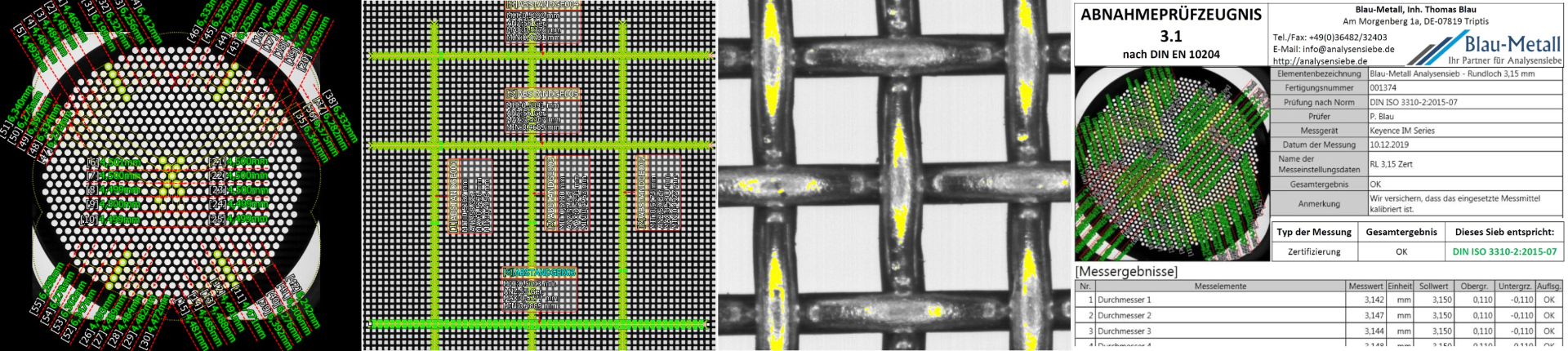

⚙ Blau-Metall offers re-certification services for all types of test sieves up to a diameter of 400 mm using state of the art Image Dimension Measurement Technology compliant with most national and international standards governing the operation of test sieves as well as customer-specific tolerances.

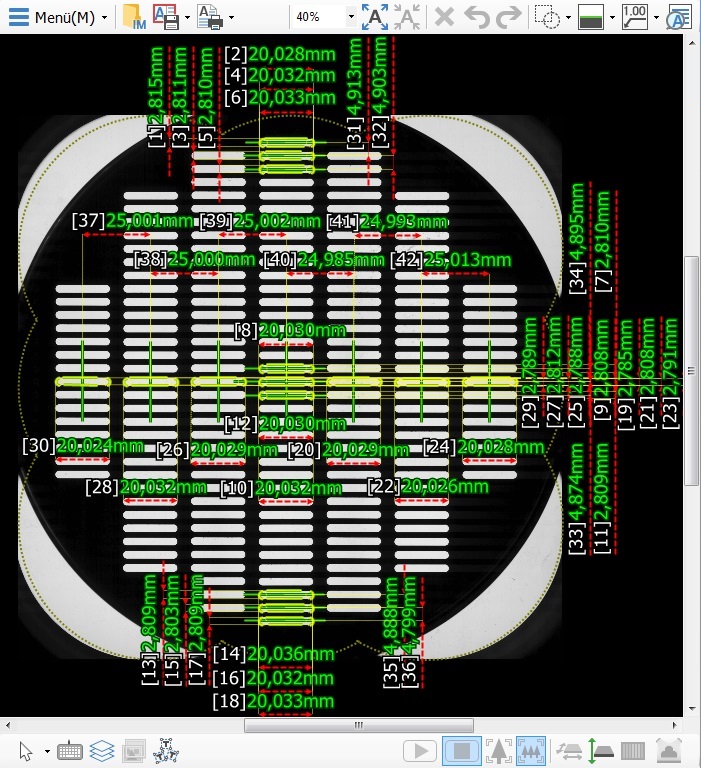

⚙ Blau-Metall offers re-certification services for all types of test sieves up to a diameter of 400 mm using state of the art Image Dimension Measurement Technology compliant with most national and international standards governing the operation of test sieves as well as customer-specific tolerances.⚙ The optical inspection is carried out in accordance with the instrumentation and methodology specified in ISO 3310-1 & -2, EN ISO 5223, ASTM E 11, ASTM E 323, etc. and the inspection certificate is issued within the guidelines of the respective standard.

⚙ Full documentation is provided to the customer in the form of Inspection Certificates 3.1 in accordance with EN 10204, satisfying the requirements of quality assurance standards such as ISO 9001. Two types of re-certification are offered by Blau-Metall:

- Certification: Inspection is carried out according to the certification requirements of the respective standard with respect to the number of apertures / pitches that are being measured,

- Calibration: The number of inspected apertures / pitches exceeds that specified in the respective standard by a factor of three or greater, increasing the statistical certainty of inspection results.

Regular inspection of test sieves ensures that they, especially when under constant use, remain compliant with the standard for which they were manufactured and provides additional confidence in constant and reliable screening results, minimizing deviations and allowing for reproducible sieving results over an extended period.

Regular inspection of test sieves ensures that they, especially when under constant use, remain compliant with the standard for which they were manufactured and provides additional confidence in constant and reliable screening results, minimizing deviations and allowing for reproducible sieving results over an extended period.When using test sieves as measuring instruments, operators are obligated under a number of standards, laws and regulations to periodically inspect their sieves – either through visual inspection in house to detect any larger irregularities or through detailed optical inspection using norm-compliant instrumentation. Defined as measuring instruments in ISO 3310, test sieves are subject of national laws governing technical and legal metrology (e.g. Bundesgesetz über das Messwesen MessG in Germany & Switzerland, MEG in Austria) as well as quality assurance regulations such as ISO 9001. Additionally, when used for specialized applications, test sieves and their operation is subject to requirements and guidelines of various agencies (e.g. grain sieves are subject of regulations imposed by government intervention boards).

Generally, under the legal terms of the majority of metrology laws, test sieves – when employed as measuring instruments in a legal sense – are to be “inspected regularly,” though the periods between inspections and the nature of the inspections themselves is left to the discretion of the operator. According to ISO 9001, an inspection is needed “at regular intervals or prior to use” whereas internal inspection by the operator or re-certification by an authorized entity are both permissible. For grain sieves, many regulations call for a mandatory annual re-certification (ref. German Federal Office for Agriculture and Food).

To satisfy the requirements for regular internal inspection, operators of test sieves can employ calibrated Normsand or standardized material samples such as glass beads for sieve calibration which yields a cursory determination whether the sieve remains norm compliant and may be sufficient for most applications. Disadvantages of these methods are mainly found in the accuracy of results obtained which, in large part, depends on the sourcing and quality of the reference materials.

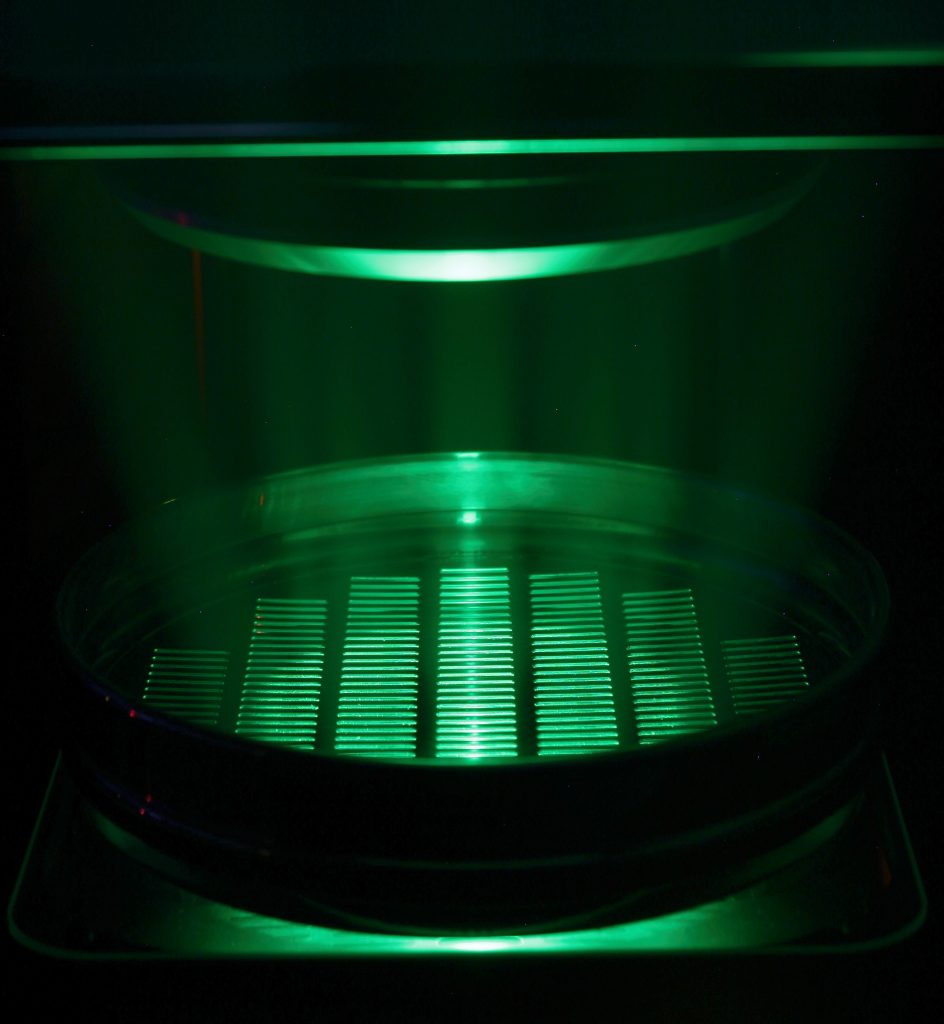

To satisfy the requirements for regular internal inspection, operators of test sieves can employ calibrated Normsand or standardized material samples such as glass beads for sieve calibration which yields a cursory determination whether the sieve remains norm compliant and may be sufficient for most applications. Disadvantages of these methods are mainly found in the accuracy of results obtained which, in large part, depends on the sourcing and quality of the reference materials.For complete metrological traceability and compliance with national / international standards, test sieves are to undergo re-certification via the methods specified in the respective standards which in most cases is an optical inspection. Blau-Metall offers norm-compliant re-certification of test sieves (including those from other manufacturers) using modern Image Dimension Measurement Technology that allows for an absolute measurement accuracy of ±5 µm in standard and ±0.5 µm in precision operation mode.

Requirements for Re-Certification:

- Sieves are to be cleaned by the customer (Ultrasonic cleaning by us is possible at additional cost)

- The sieves must be free of harmful contaminants

- A declaration of no objection has to be provided by the customer with the shipment of sieves (Download Form)

German Website

German Website